What drove you to remove the scuttle panel and investigate further ? I bet your glad you did!

Only way I could be happy, it was always about me being able to know its rust free as possible, even where you can't see. As it was knew about the rust on the scuttle panel because it was visible from inside, however I would have removed it anyway as its a known common area for bad rust on these as its a water trap.

But how far do you plan to go - as previously said in other threads - there's probably rust inside every seam on the car.

As far as I can realistically, anywhere thats a known problem area or anywhere that taking it apart is not too complicated.

Update Time

Strip the boot and get it in primer:

Its not the flattest boot, and someone has drilled holes in it, but it will work just fine after some love.

Time for the other side

As she stood before the surgery started:

The operation beings, lets cut off that scrap quarter panel and see what awaits, expecting similar to the other side:

Could be worse, although someone has used some seam sealer as an alternative to weld.

Rocker, arch and rear panel support removed

Cancer

A closer look at the cancer:

Thats different to the other side:

Cancer Gone

Without the fuel filler, the panel support is much simpler on this side:

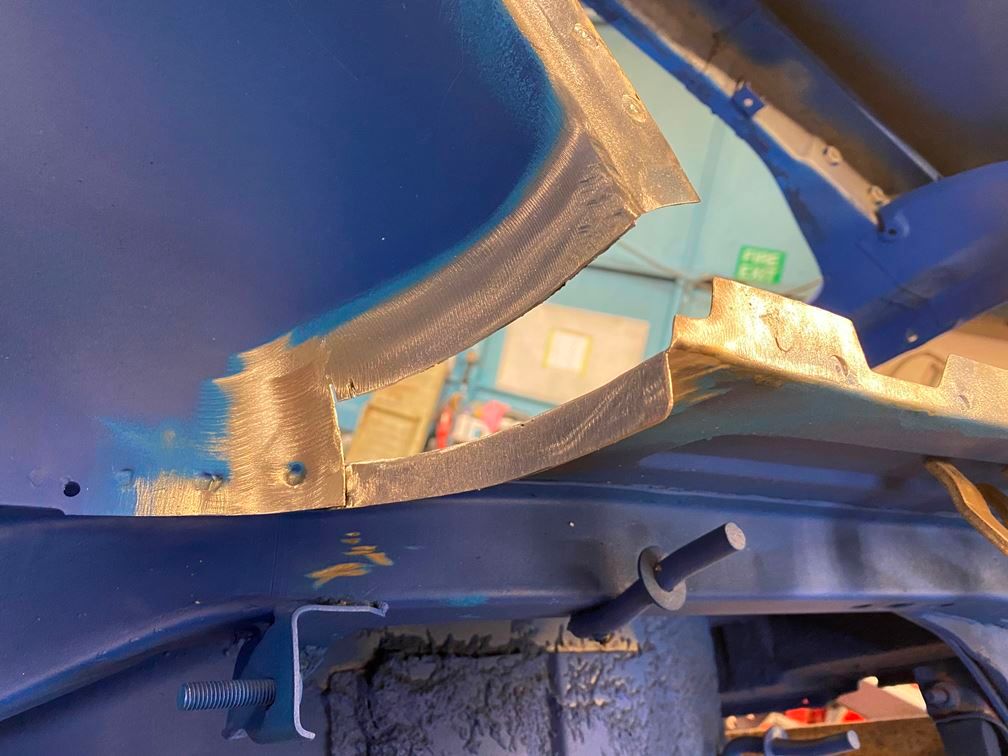

Just the complicated front area to do now:

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)