darren-b

Well-Known Forum User

Hi all, thought I would post up a new thread for the re-build of the 240z I bought back in July

http://zclub.net/forum/showthread.php?t=24447

After sorting out a few critical bits, (lights, shocks, steering gators) I've spent the last 6weeks enjoying the car, including a 850mile round trip to Wales, where the car performed very well.

So now that the Autumn is here it's time to start the strip down today.

Whilst awaiting my hangover to wear off I decided to start removing the interior, so started with the carpets, to reveal the original white vinyl which is in a pretty poor state & I realised that there are some parts missing. I'll probably just scrap the white interior all together & go black as I can source all the parts in black fairly easily.

I then got bored with the interior after removing the centre console so decided I may aswell make use of the afternoon. So got underneath & removed the exhaust with no snapped bolts

All out in one piece

Then onto removing the gearbox, drained the oil out, removed the prop shaft, unbolted & removed (didn't take pictures as I was covered in oil)

Then proceeded to drain the engine oil & coolant

Removed the Radiator, HT leads & labelled all connecting wires in the engine bay

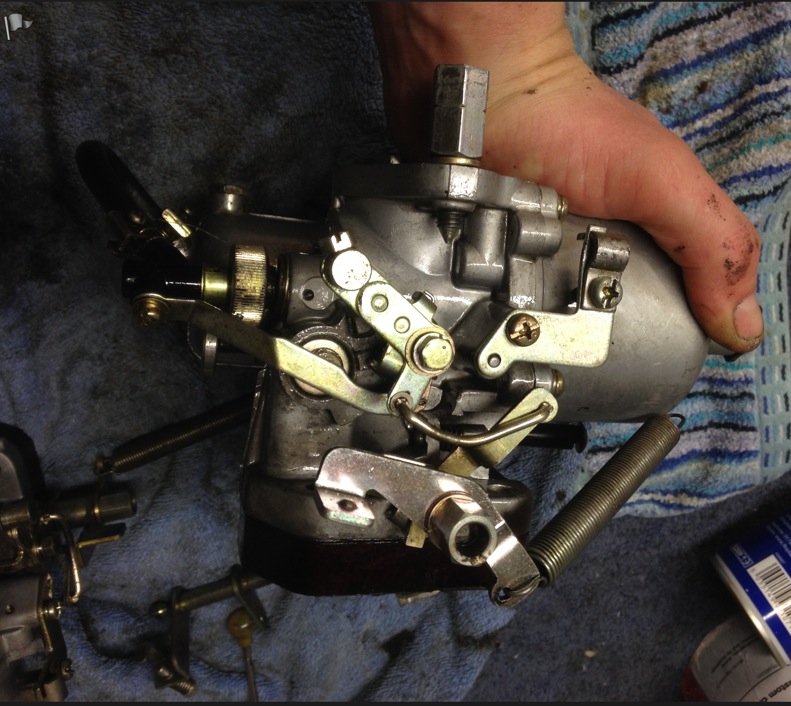

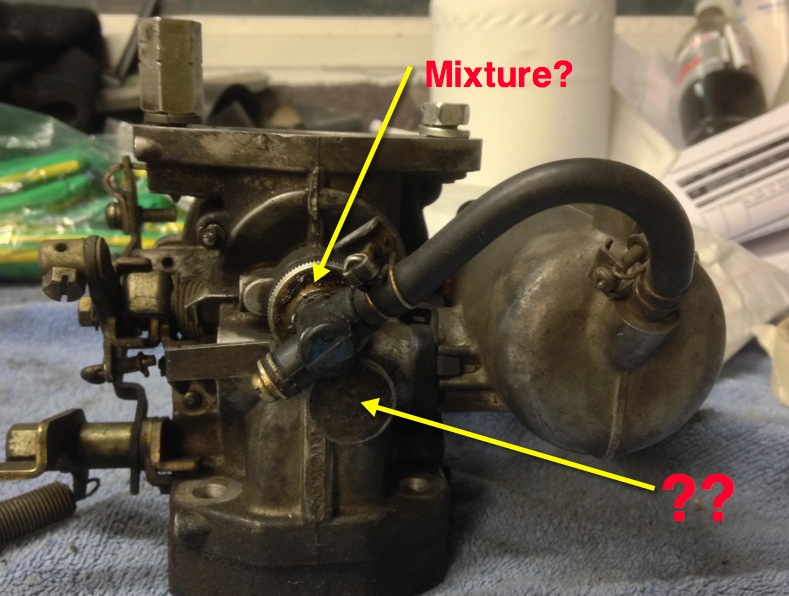

Then disconnected the fuel lines & removed the carbs

Then got to work with my new toy

At this point I was almost laughing to myself how easy the job was, until I got to here:

Maximum height on the crane I already had to jack the car up to clear the support arms under the wishbones where the car a very narrow track & the front radiator support is welded in rather than bolted so I couldn't remove that.

I already had to jack the car up to clear the support arms under the wishbones where the car a very narrow track & the front radiator support is welded in rather than bolted so I couldn't remove that.

It was already about 4ish so going out to buy a winch/hoist was out of the question. I needed more height. So a little modification to the crane was the answer:

Which gave me plenty of height

So rolled the car back

& then she was naked

I need to look a little closer @ the crane mod as now the lowest height still holds the engine around 200mm from the floor

Need to make a proper stand for it in the week so that I can get it cleaned & stripped down

All in all a fairly fun afternoon

http://zclub.net/forum/showthread.php?t=24447

After sorting out a few critical bits, (lights, shocks, steering gators) I've spent the last 6weeks enjoying the car, including a 850mile round trip to Wales, where the car performed very well.

So now that the Autumn is here it's time to start the strip down today.

Whilst awaiting my hangover to wear off I decided to start removing the interior, so started with the carpets, to reveal the original white vinyl which is in a pretty poor state & I realised that there are some parts missing. I'll probably just scrap the white interior all together & go black as I can source all the parts in black fairly easily.

I then got bored with the interior after removing the centre console so decided I may aswell make use of the afternoon. So got underneath & removed the exhaust with no snapped bolts

All out in one piece

Then onto removing the gearbox, drained the oil out, removed the prop shaft, unbolted & removed (didn't take pictures as I was covered in oil)

Then proceeded to drain the engine oil & coolant

Removed the Radiator, HT leads & labelled all connecting wires in the engine bay

Then disconnected the fuel lines & removed the carbs

Then got to work with my new toy

At this point I was almost laughing to myself how easy the job was, until I got to here:

Maximum height on the crane

It was already about 4ish so going out to buy a winch/hoist was out of the question. I needed more height. So a little modification to the crane was the answer:

Which gave me plenty of height

So rolled the car back

& then she was naked

I need to look a little closer @ the crane mod as now the lowest height still holds the engine around 200mm from the floor

Need to make a proper stand for it in the week so that I can get it cleaned & stripped down

All in all a fairly fun afternoon