-

The Z Club relies on the support of it's paid members - join the club or renew your membership here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Here we go again Derricks 260z restoration

- Thread starter candy red

- Start date

candy red

Club Member

The car is mostly solid but does have a lot of patches that need to be removed an make new panels to good

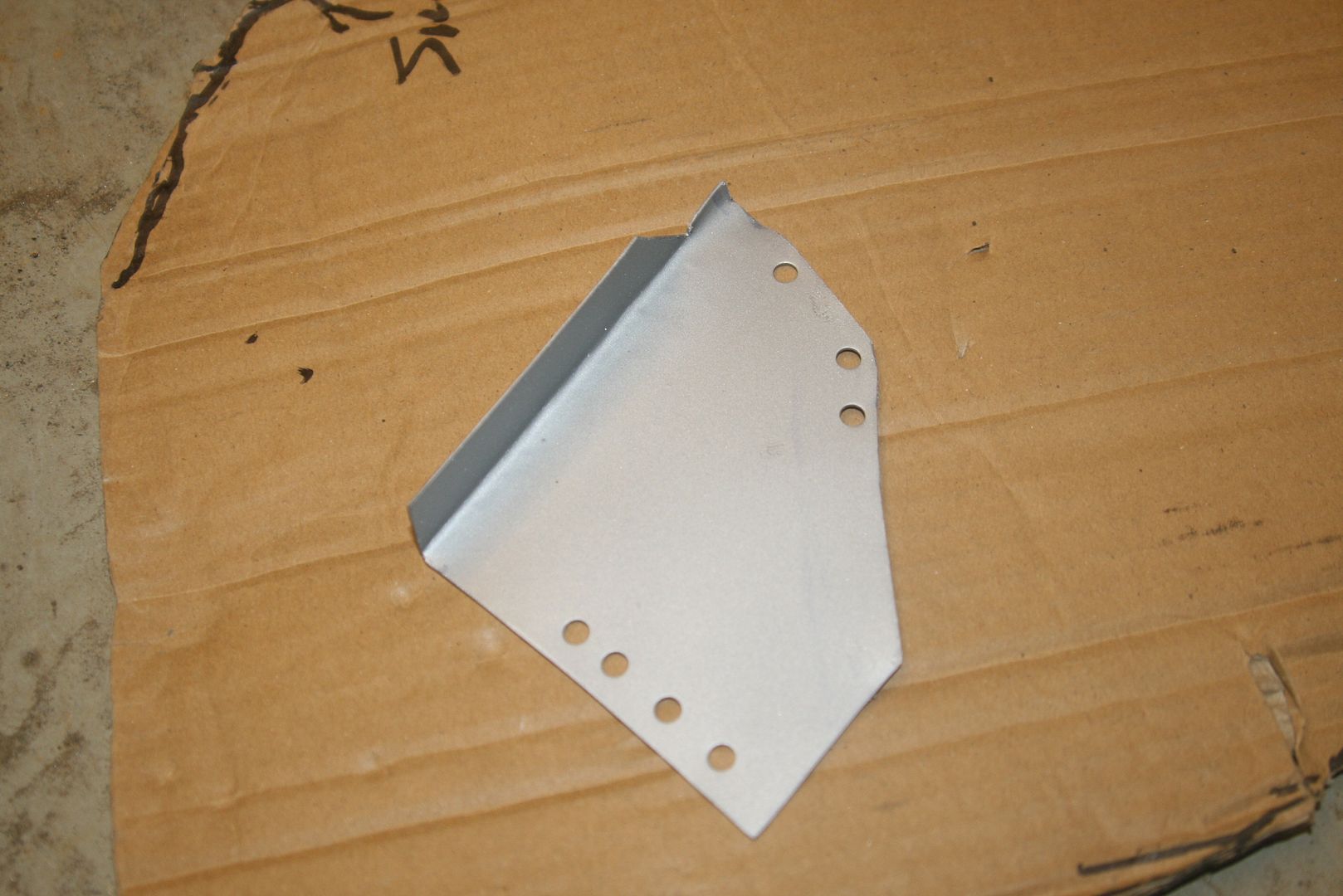

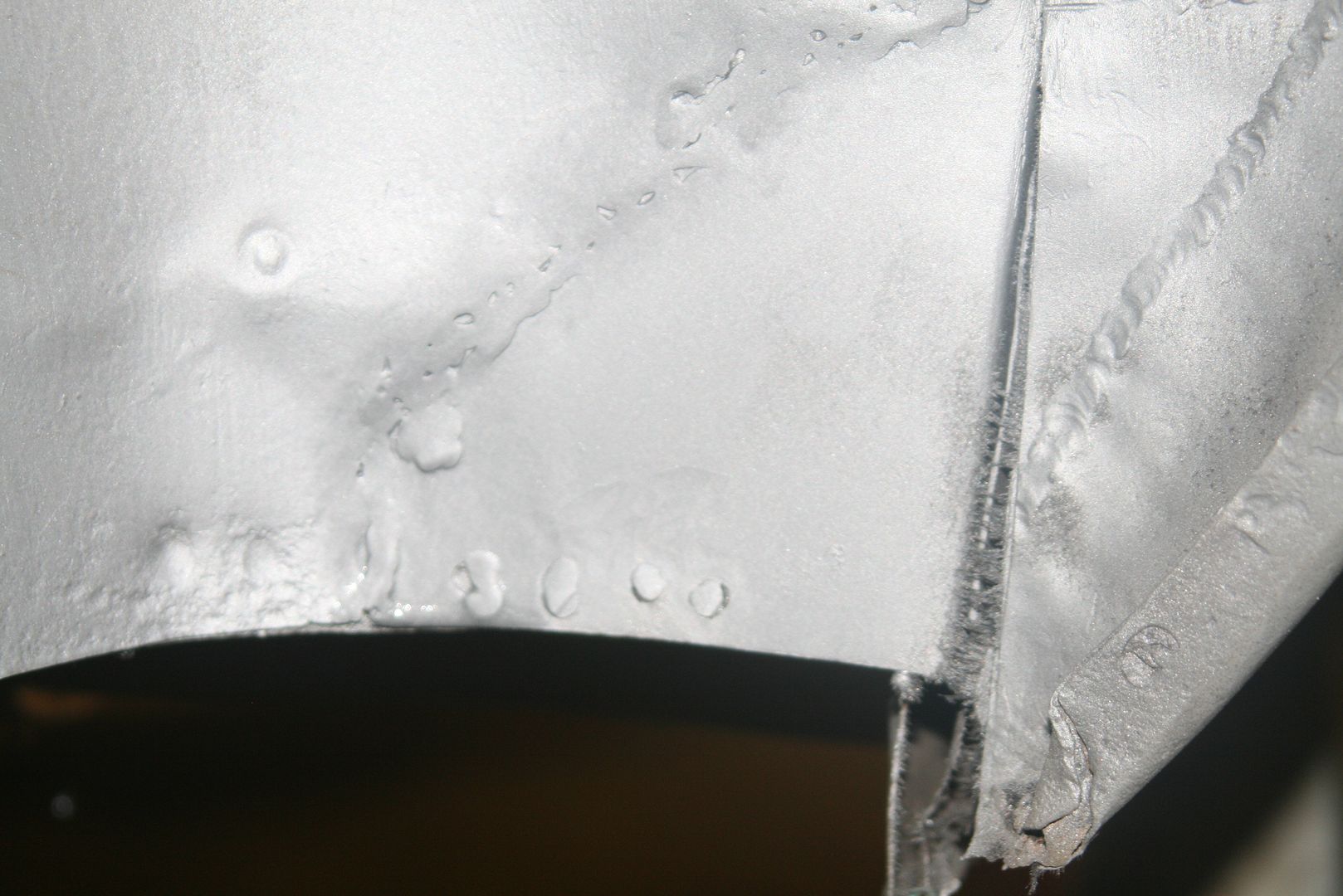

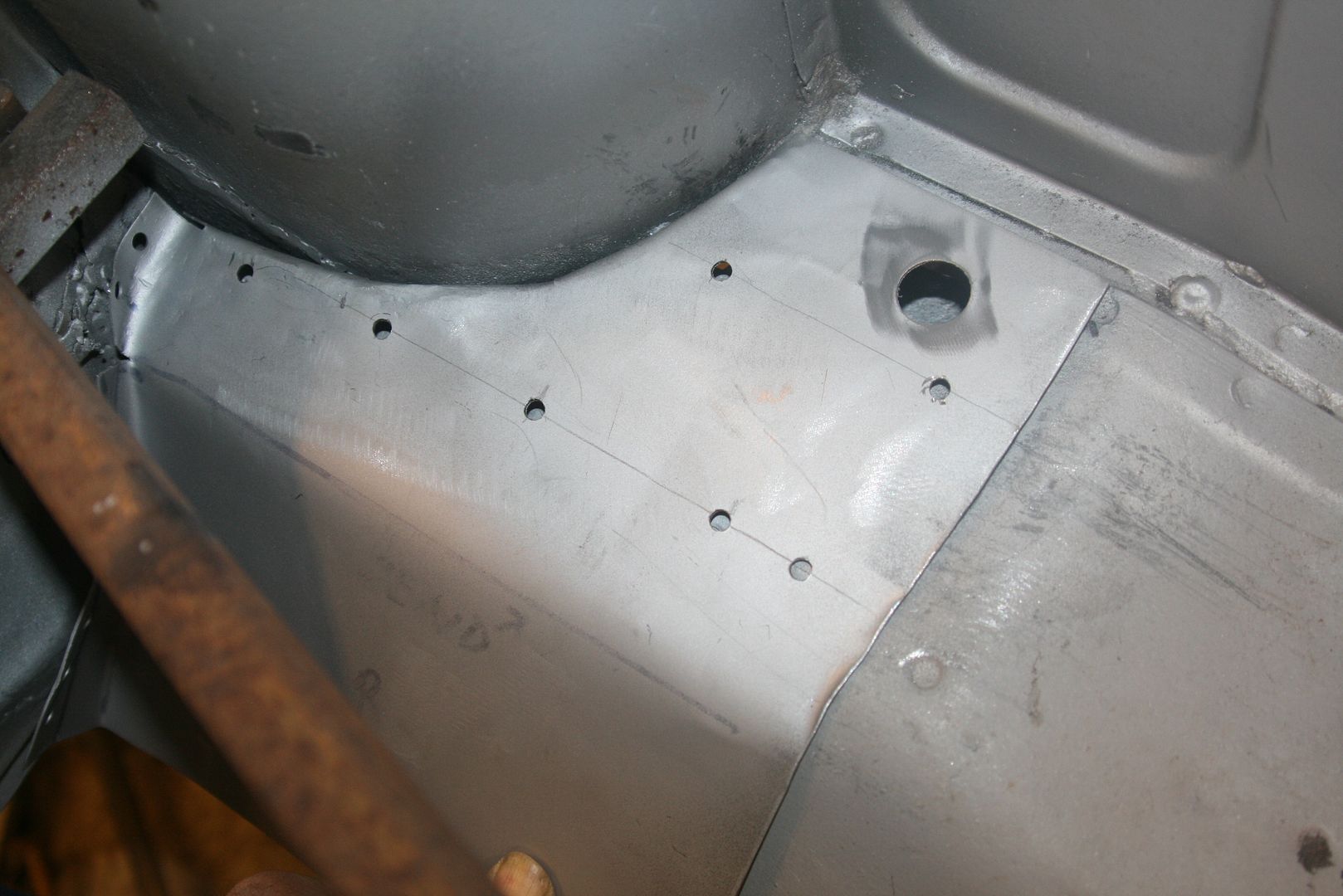

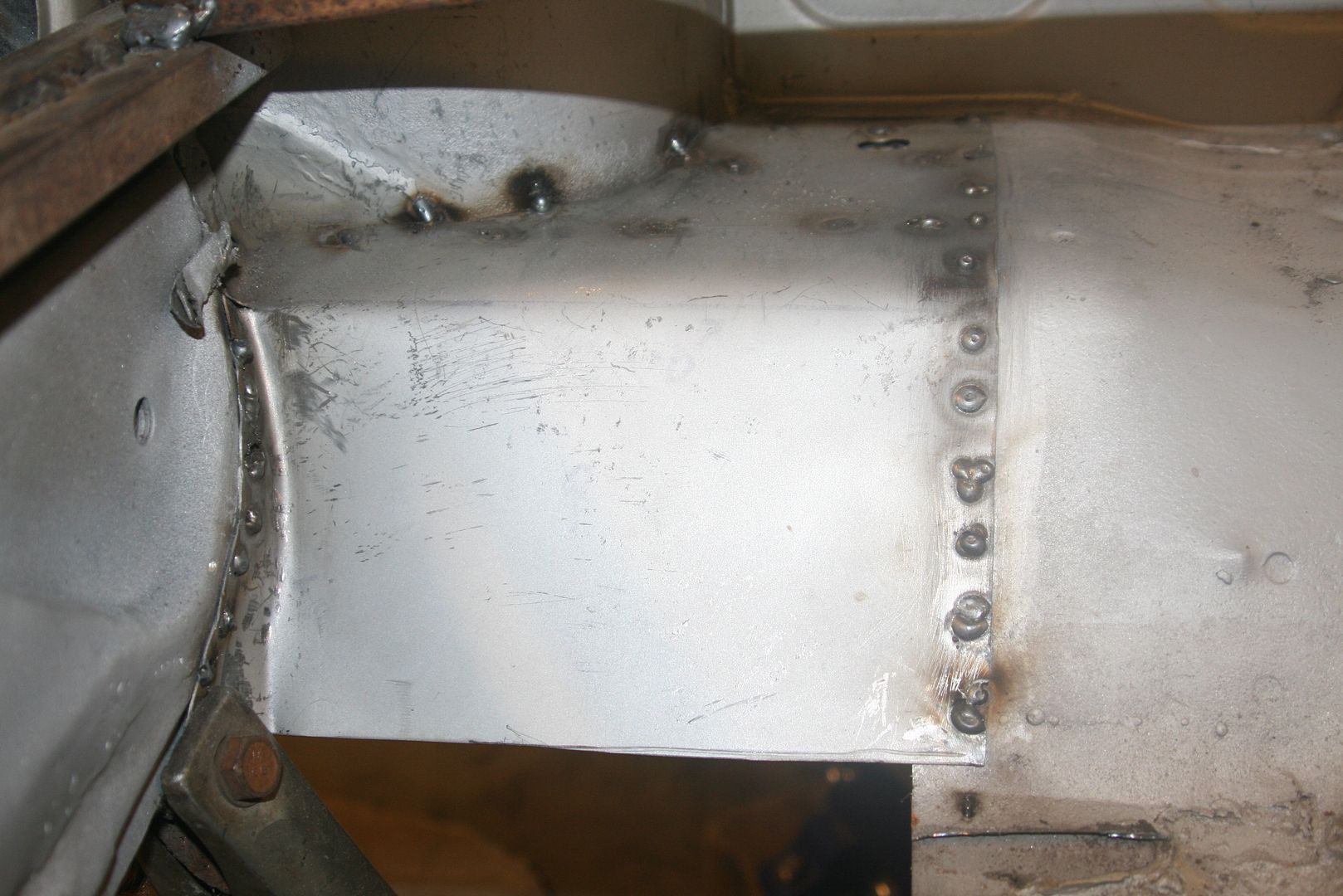

Heres a few panels that I've made 2x footwell panels to replace the 4 patches in left and right footwell and 2 panels to repair rear of floor where it meets the rear wheel arch and will join the new floor pans

just trying in the drivers side footwell panel need a little more shaping

Derrick

Derrick

also jacked the car up so the weight was no longer on The rotisserie

also jacked the car up so the weight was no longer on The rotisserie