MarkDerby

Well-Known Forum User

Ok Lets start by Finding a Sub box that will look nice in the car

sorry if its been posted a few times before

as you can see its quite nice .. but it does have one Problem

box isnt the right size for the speakers

so anyways this is what im about to show you ...

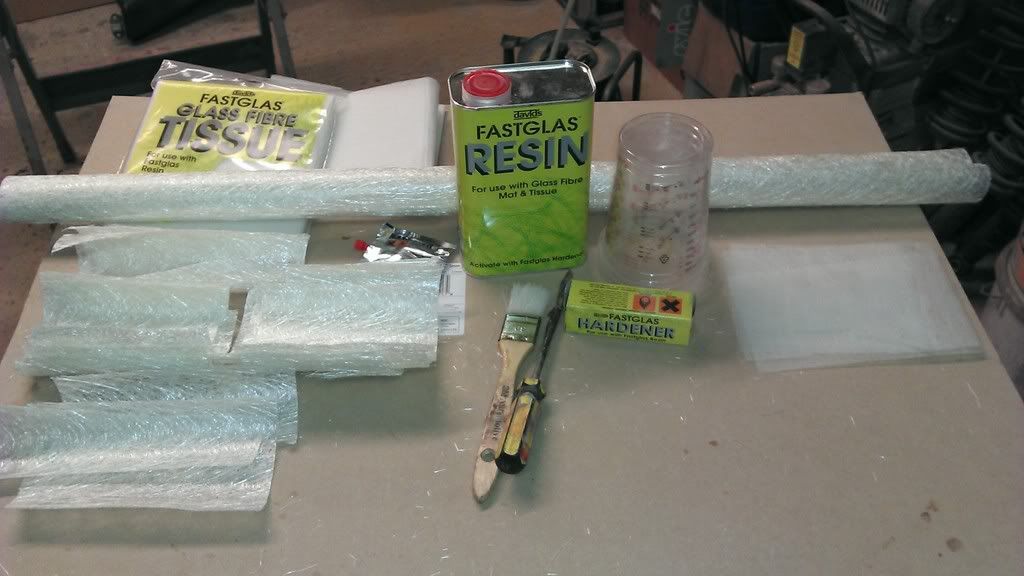

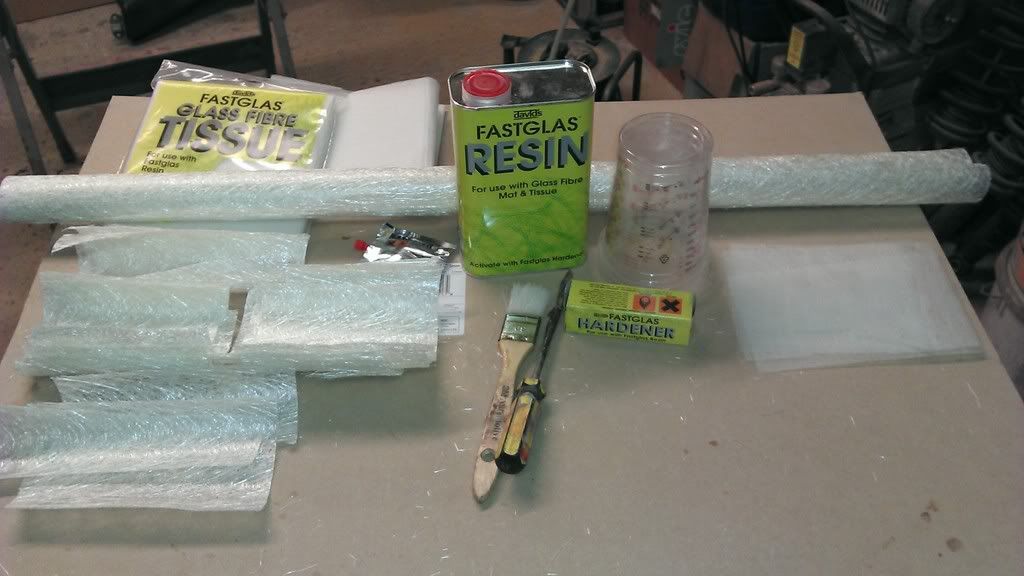

First you will need some Items from Hardware stores

18mm MDF

2x2 timber

Fiber Glass Resin 4liters

Resin Hardener 2 tubes

Fiber Glass Medium grade 3 meters

Fiber Glass Tissue 1 meter

Hard Brush 2

Pots 5

Fleece about 1mtx1mt

Port Hole ( if your fitting one )

you first have to Prep the place your going to make your mold from

so i used Duck Tape but you can use masking tape too

It would be handy to have some old cardboard too

this will help to make templates

As you can see this allowed me to get the correct shape for the Base part of the box

you need to mix some harder and resin together i did this at 250mm a time with about this much resin hardener all so make sure you mix it well it should turn Pink and have little bubbles this has started the reaction of the resin you will have about 5>10 mins to use it before it start to go like gelly

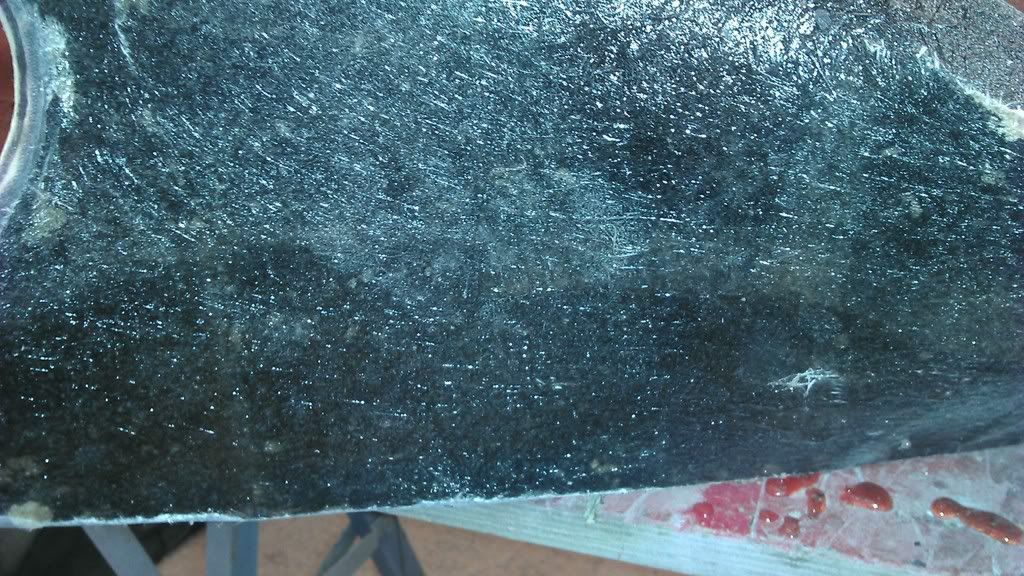

ok this is where the fun starts

you first need to coat the Mold with Resin

then have your PreCut fiber glass to hand to start applying

once you have done your first Layer of fiber glass leave it over night to set

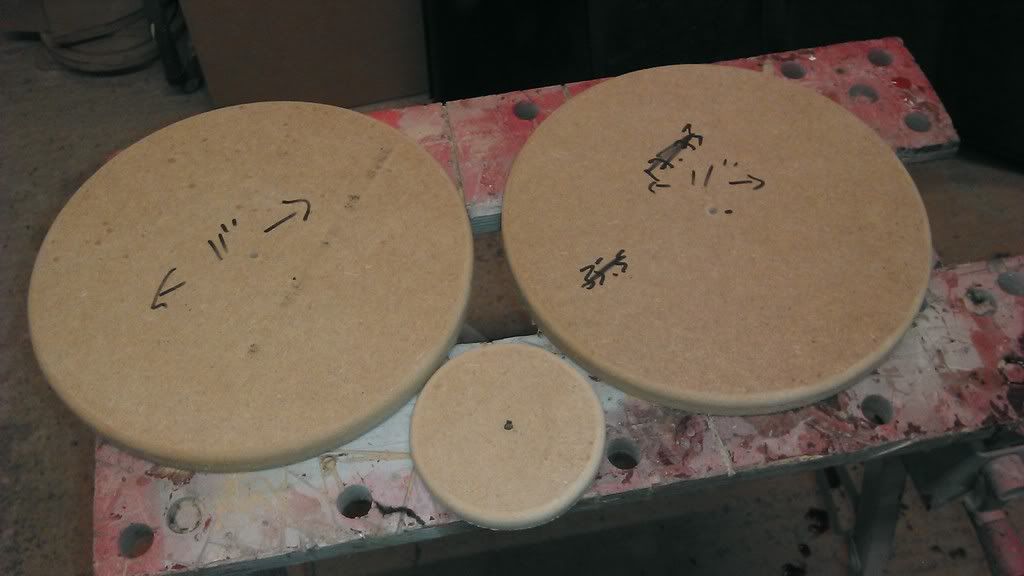

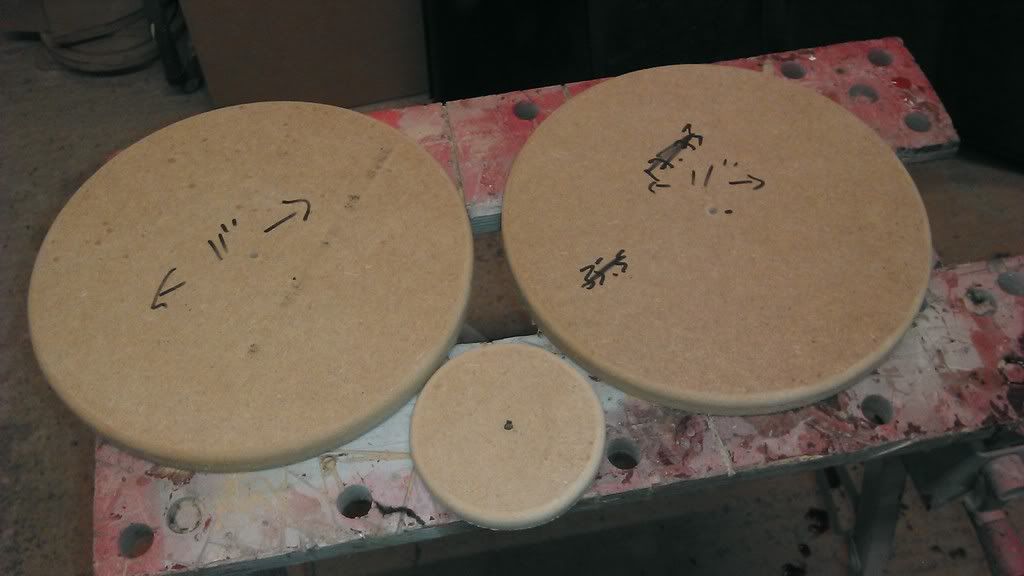

but why wast time when you can start to make other items needed like the speaker Rings

make sure you have your speaker sizes to hand

i'm making the box for twin 10" subs

total outer size of rings are 11" wide and will have a 9" inner cut out

OK once you have done one layer of fiber glass its time to make some more templates for bracing

sorry if its been posted a few times before

as you can see its quite nice .. but it does have one Problem

box isnt the right size for the speakers

so anyways this is what im about to show you ...

First you will need some Items from Hardware stores

18mm MDF

2x2 timber

Fiber Glass Resin 4liters

Resin Hardener 2 tubes

Fiber Glass Medium grade 3 meters

Fiber Glass Tissue 1 meter

Hard Brush 2

Pots 5

Fleece about 1mtx1mt

Port Hole ( if your fitting one )

you first have to Prep the place your going to make your mold from

so i used Duck Tape but you can use masking tape too

It would be handy to have some old cardboard too

this will help to make templates

As you can see this allowed me to get the correct shape for the Base part of the box

you need to mix some harder and resin together i did this at 250mm a time with about this much resin hardener all so make sure you mix it well it should turn Pink and have little bubbles this has started the reaction of the resin you will have about 5>10 mins to use it before it start to go like gelly

ok this is where the fun starts

you first need to coat the Mold with Resin

then have your PreCut fiber glass to hand to start applying

once you have done your first Layer of fiber glass leave it over night to set

but why wast time when you can start to make other items needed like the speaker Rings

make sure you have your speaker sizes to hand

i'm making the box for twin 10" subs

total outer size of rings are 11" wide and will have a 9" inner cut out

OK once you have done one layer of fiber glass its time to make some more templates for bracing