-

The Z Club relies on the support of it's paid members - join the club or renew your membership here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'74 260z project

- Thread starter morbias

- Start date

morbias

Well-Known Forum User

Cheers for the comments guys, it's nice to be given some motivation, especially now it's freezing cold out there!

Stockdale - when was your car registered? Mine was first registered in the UK in February '74; I only ask because my number plate is BTU 66M and I have seen a few other S30s with very similar plates and I assume that's because they were registered all at once.

MaximG - It came up OK, it would've been better if I'd taken more time to grind the weld down, but as it is it looks like this:

It's a lot better than it was and isn't too noticeable so I'm not too bothered but I'm sure you could get a better result if you put in more effort than I did.

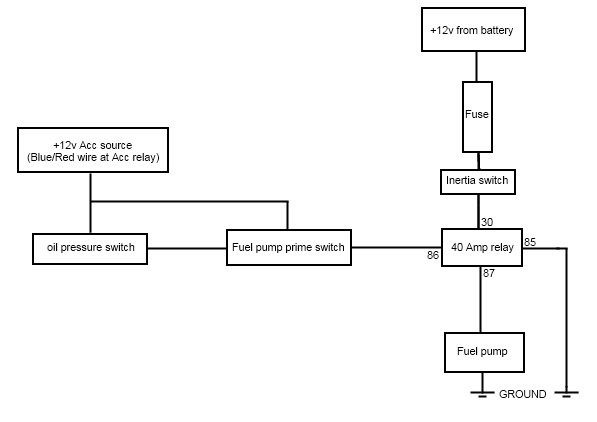

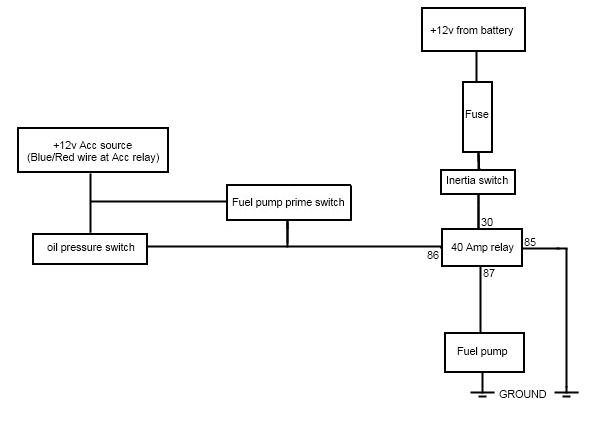

I've been working out a circuit diagram of how I'm going to wire in an electric fuel pump, would this work?

Stockdale - when was your car registered? Mine was first registered in the UK in February '74; I only ask because my number plate is BTU 66M and I have seen a few other S30s with very similar plates and I assume that's because they were registered all at once.

MaximG - It came up OK, it would've been better if I'd taken more time to grind the weld down, but as it is it looks like this:

It's a lot better than it was and isn't too noticeable so I'm not too bothered but I'm sure you could get a better result if you put in more effort than I did.

I've been working out a circuit diagram of how I'm going to wire in an electric fuel pump, would this work?

datsun dave

Club Member

I have put my fuel pump fuses inside the car you can then remove them to stop the car going missing as no fuse no fuel to the engine.

I've been working out a circuit diagram of how I'm going to wire in an electric fuel pump, would this work?

Can you explain the priming switch operation? What I want to know is how is the oil pressure switch 'out then in' circuit. Is the priming circuit a function of the starter cct or manual?

morbias

Well-Known Forum User

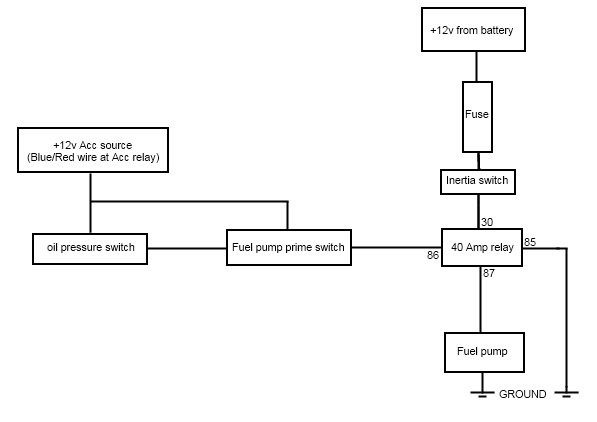

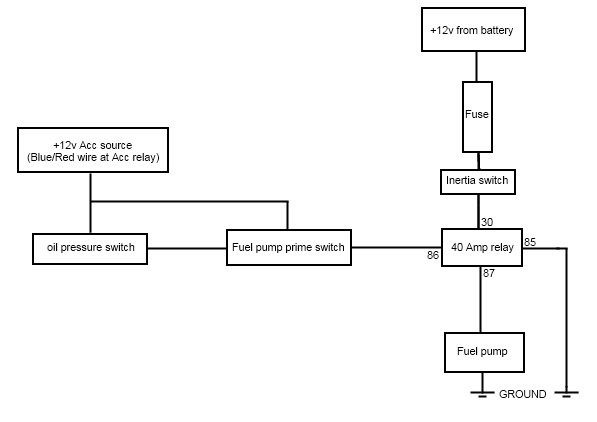

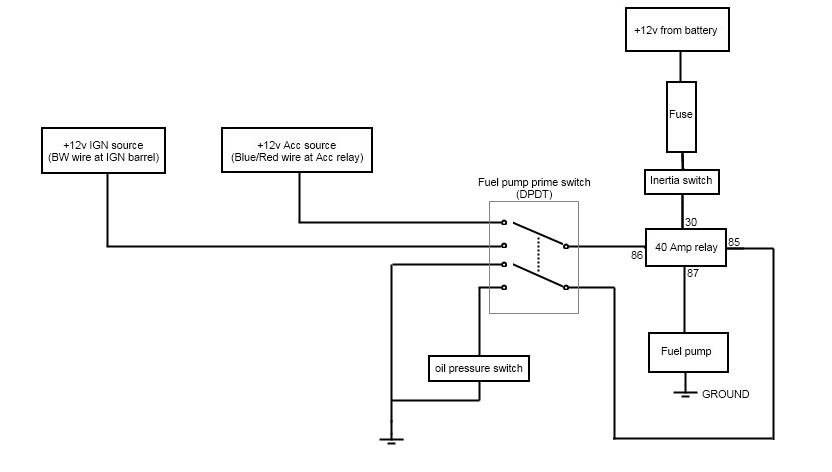

oops, I made a mistake, it should look like this:

The prime switch bypasses the oil pressure switch so the carbs can be manually filled with the ignition turned to the accessory on position.

[EDIT] is the +12v acc source a good wire to use for activating the fuel pump relay? Looking at wiring diagrams of the original Nissan electric assist pump it uses the BW wire at the ignition barrel, but that's only live when the car is running.

The prime switch bypasses the oil pressure switch so the carbs can be manually filled with the ignition turned to the accessory on position.

[EDIT] is the +12v acc source a good wire to use for activating the fuel pump relay? Looking at wiring diagrams of the original Nissan electric assist pump it uses the BW wire at the ignition barrel, but that's only live when the car is running.

Last edited by a moderator:

[EDIT] is the +12v acc source a good wire to use for activating the fuel pump relay? Looking at wiring diagrams of the original Nissan electric assist pump it uses the BW wire at the ignition barrel, but that's only live when the car is running.

So when you are sitting listening to the radio the pump is ticking away? With your updated diagram you are still not going to have the oil pressure switch serving a purpose because it's never in circuit until the ignition switch is in the is off position!

morbias

Well-Known Forum User

Surely the oil pressure switch is only feeding the pump relay when the acc source is active? I see your point though about having the pump running without the engine running. So I should use the BW wire for the oil pressure switch which is only active when the engine is running, and the RL acc wire for the prime switch. Thanks for pointing that out!

[EDIT] Oh I think I see what you mean - I was confused because the acc is live when the engine is running

[EDIT] Oh I think I see what you mean - I was confused because the acc is live when the engine is running

Last edited by a moderator:

Surely the oil pressure switch is only feeding the pump relay when the acc source is active? I see your point though about having the pump running without the engine running. So I should use the BW wire for the oil pressure switch which is only active when the engine is running, and the RL acc wire for the prime switch. Thanks for pointing that out!

Ok so that prime switch is manually switched and turned off before you start the engine?

Yes, if the car has been sitting for a while I can use it to fill the float bowls  (shouldn't need to though

(shouldn't need to though  as the pump will be next to the fuel tank) or just for testing for leaks etc.

as the pump will be next to the fuel tank) or just for testing for leaks etc.

(shouldn't need to though

(shouldn't need to though morbias

Well-Known Forum User

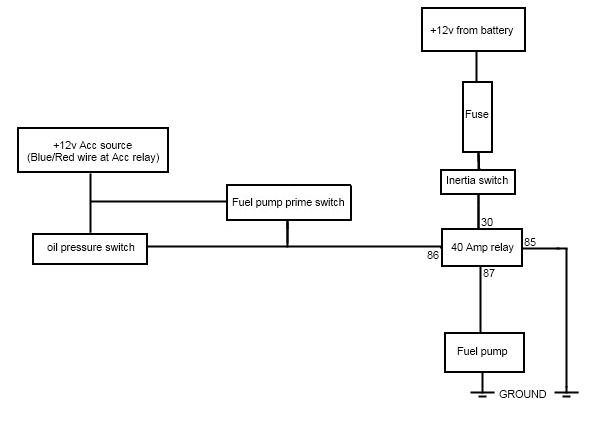

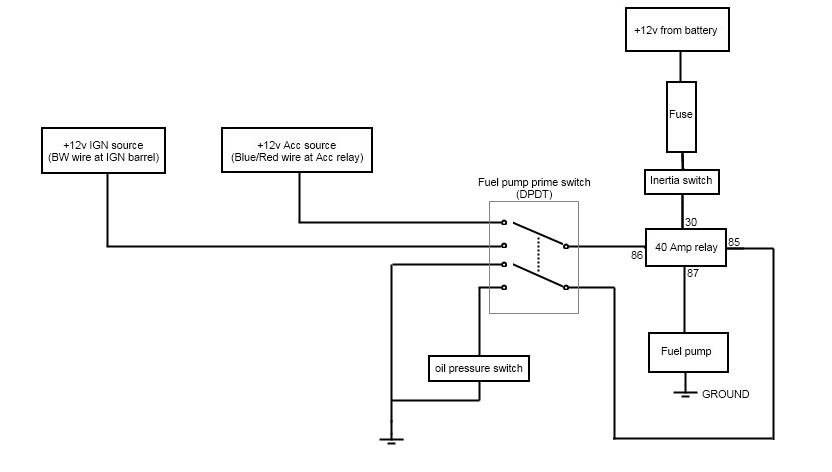

Well it turns out I could only find one company in the US that makes an oil pressure switch that would fit that circuit diagram, so that is out of the window. All normal oil pressure switches connect the contact to ground, so, fuel pump circuit diagram version 3...

It all seems a bit complicated. I just had my pump wired to the ignition and let it fill the carbs before turning all the way to the starting position.

If I had a megga expensive race engine then the oil pressure switch would be a good idea,

If I had a megga expensive race engine then the oil pressure switch would be a good idea,

morbias

Well-Known Forum User

I'm using it as a safety feature along with the inertia switch, just in case the worst happens and I have a big crash.

I've realised that I can source the blue/red Acc feed at the ignition barrel along with the black/white wire so that will make the wiring easier to route. Also I'm going to put the inertia switch on the 86 terminal of the relay so it doesn't carry the full load current of the pump.

I've spent the last couple of days sectioning the struts, what a mission! It's taken longer than I was expecting (surprise, surprise), though only because I re-measured over and over to make sure I wasn't going to screw it up. Getting all four struts off the car and dismantled only took me 2 hours, I'm getting good at it now...

I've realised that I can source the blue/red Acc feed at the ignition barrel along with the black/white wire so that will make the wiring easier to route. Also I'm going to put the inertia switch on the 86 terminal of the relay so it doesn't carry the full load current of the pump.

I've spent the last couple of days sectioning the struts, what a mission! It's taken longer than I was expecting (surprise, surprise), though only because I re-measured over and over to make sure I wasn't going to screw it up. Getting all four struts off the car and dismantled only took me 2 hours, I'm getting good at it now...