Its been a while since I’ve updated my thread, so here is a potted history of work over the summer.

While the car was away being sprayed I continued with the engine rebuild. After taking lots of advice from many members I decided to completely rebuild the motor in favour of just a head rebuild. This turned out to be a very wise move, thanks pmac for the advice. Once I removed the head and stripped the block I found all manor of horrors.

Before I took the car off the road many years ago, it was prone to overheating. With the head off I found heat damage to number six cylinder and what I though was sever rusting of the block once the core plugs were removed. A yellow orangey powder pored out of the rear of the block when I removed the core plugs. The block drain plug was completely blocked up with the stuff. As it turns out, this was not all rust, but a mix of rust and casting sand, a lot of casting sand, from the original casting process. I’m surprised the engine never went bang sooner. Good old Japanese mass production at its best.

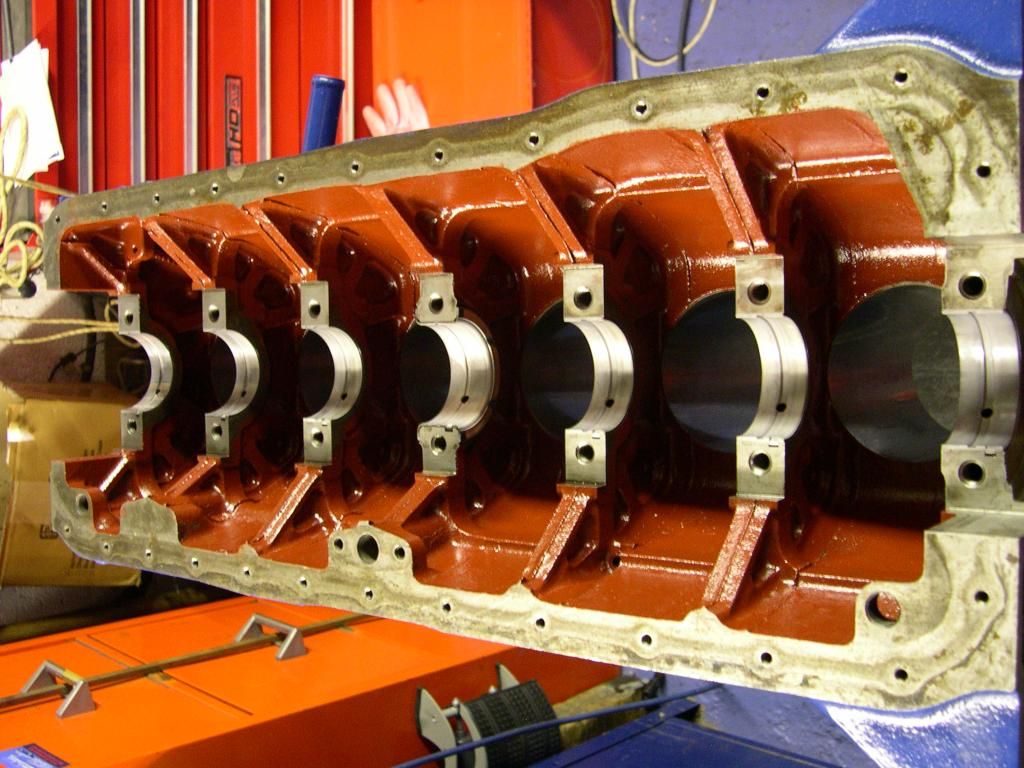

With the block stripped and dipped, it needed a re-bore to sort the damage to number six and the deck was skimmed to remove some pitting on the surface. As it turned out it was not as serious as I first thought.

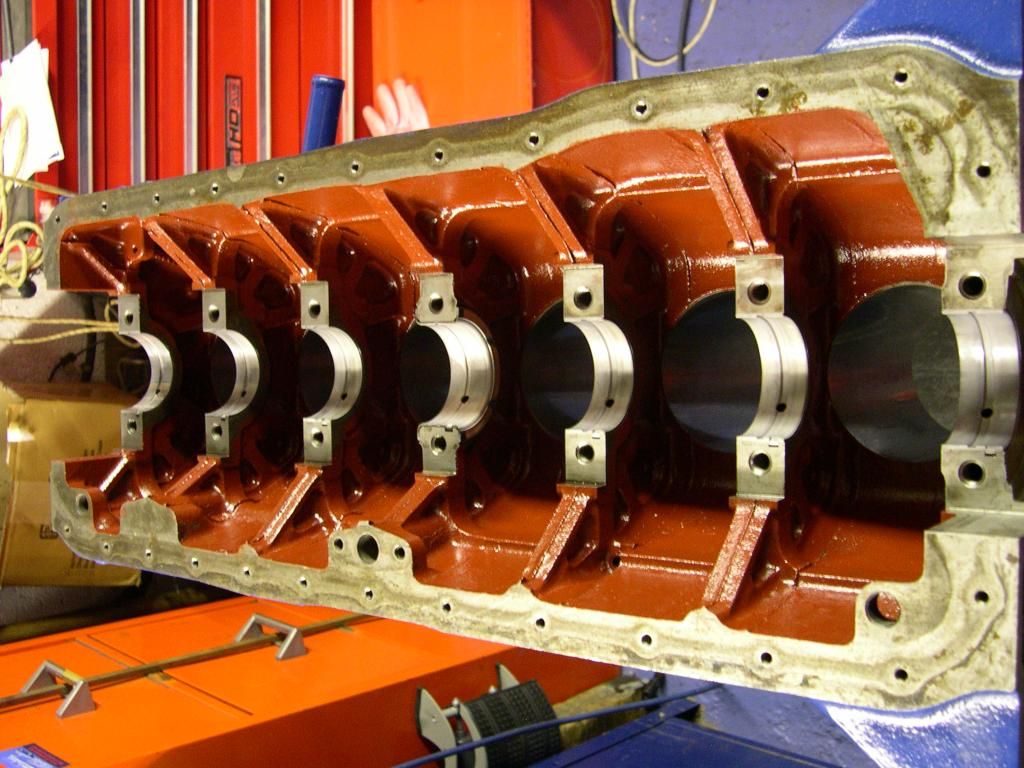

The inside got a nice coat of Glyptal, cos I’ve always wanted to do that to an engine. The crank did not need any work as it was well with in tolerances, which was a surprise. The rods were checked while they were out and found to be fine. So new pistons, rings and bearings were fitted to finish off the work to the block.

Attention was then given to the head and this is where it went horribly wrong and got expensive. This is the first overhead cam engine I’ve rebuilt and probably not a good one to start with. Side valve engines are soooo much easier to do.

I had the head skimmed, inserts fitted to the valve guides and the valve seats resurfaced – easy I thought. When I got the head back and merrily fitted all the valve train back together I found there was no adjustment left in the rockers and the lash wipe pattern was well off. Problem was the machine shop had cut the seats so far back the seats needed to be replaced. After lots more messing about, new seats and valves fixed it. But it still needed odd size lash pads to fix some of the variances in valve stem height. I had these ground to size by a precision toolmaker from oversize pads from the states. The next challenge was the timing chain.

This rebuild was a real journey for me and the one thing I take away from it is to be REAL sure the machine shop you use knows Datsun heads and then just don’t take their word for it at face value like I did and paid heavily for it. Also always buy your bits from Mr F. as they will bloody fit! Unlike like the timing kit I foolishly bought off eBay. There was so much slop in the cam sprocket it was impossible to set the timing. It was worse that the worn one I took off in the first place.

I had the sump powder coated and all the nuts, bolts and fittings gold zinc plated as I wanted a gold and blue theme for the engine. I’m glad I did go down the plating route as the water pipes that run around the front of the engine came back full of holes where the plating process removed the rust that had been holding them together, but looking at them before hand you would not have know they where rusty!

The rocker cover I’ve had powder coated in candy apple blue to match the air box I’ve also had done. I also had the exhaust manifold ceramic-coated silver just for the hell of it. All the aluminium castings have been vapour blasted to remove the corrosion, I did not want them polished and the finish from the process leaves them a lovely mat kind of finish.

As most of the rubber hosing on mine was way passed it, its all been replaced using silicon hosing, which came in blue – which was nice. The cost of having a few hoses made up as special items was not that bad and way comparable with available new rubber hoses (which didn’t come in blue).

So the engine is now as near finished as possible and awaiting being reunited with the body, but I’m waiting for the wheels to come back from being refurbished before I can do that.

I’ve also rebuilt the front brake callipers, I had them blasted, zinc plated and then powder coated a nice light blue, which will go really nicely with the aluminium/silver of the wheel when they are done. All the plating, powder coating has been done by a motorcycle custom shop in Bristol, I would really recommend them if anyone is interested.

That it for now, there are more photos in my albums. Will post more as I do it.