Ian

Club Member

How the car is sitting, metalwork, welding and painting should begin on Monday, slower than I'd like, but what can I do:

You can see how badly this has been welded/repaired previously, bad pigeon **** welds not even ground down, random patches of metal rather than a full section cut to shape, theres even a few holes in the lines, this will all be fixed properly and strengthend.

Repainted the new shafts as I wasn't happy with the paint on them, also painted the cv's in a funky blue:

[/URL]

[/URL]

Bought some nice wheel nuts, they have to be open as I've got extended wheel studs all round. I had bought some cheap chrome ones but not all of them threaded on nicely and they galled badly on the wheels. These ones are very light (only 26 grams each) look great and the top of the seats spin freely from the main body so that they don't damage the wheel and allow equal torqueing all round:

New clutch master cylinder as my original one had seen better days, works fine but was quite corroded at the back:

Battery cable cut to the correct lenths, battery mounted power shut off switch, some more random wiring and a steering wheel cover to keep my new wheel clean:

Rebuilt my steering rack today and mounted it on the crossmember:

Got the engine built back up:

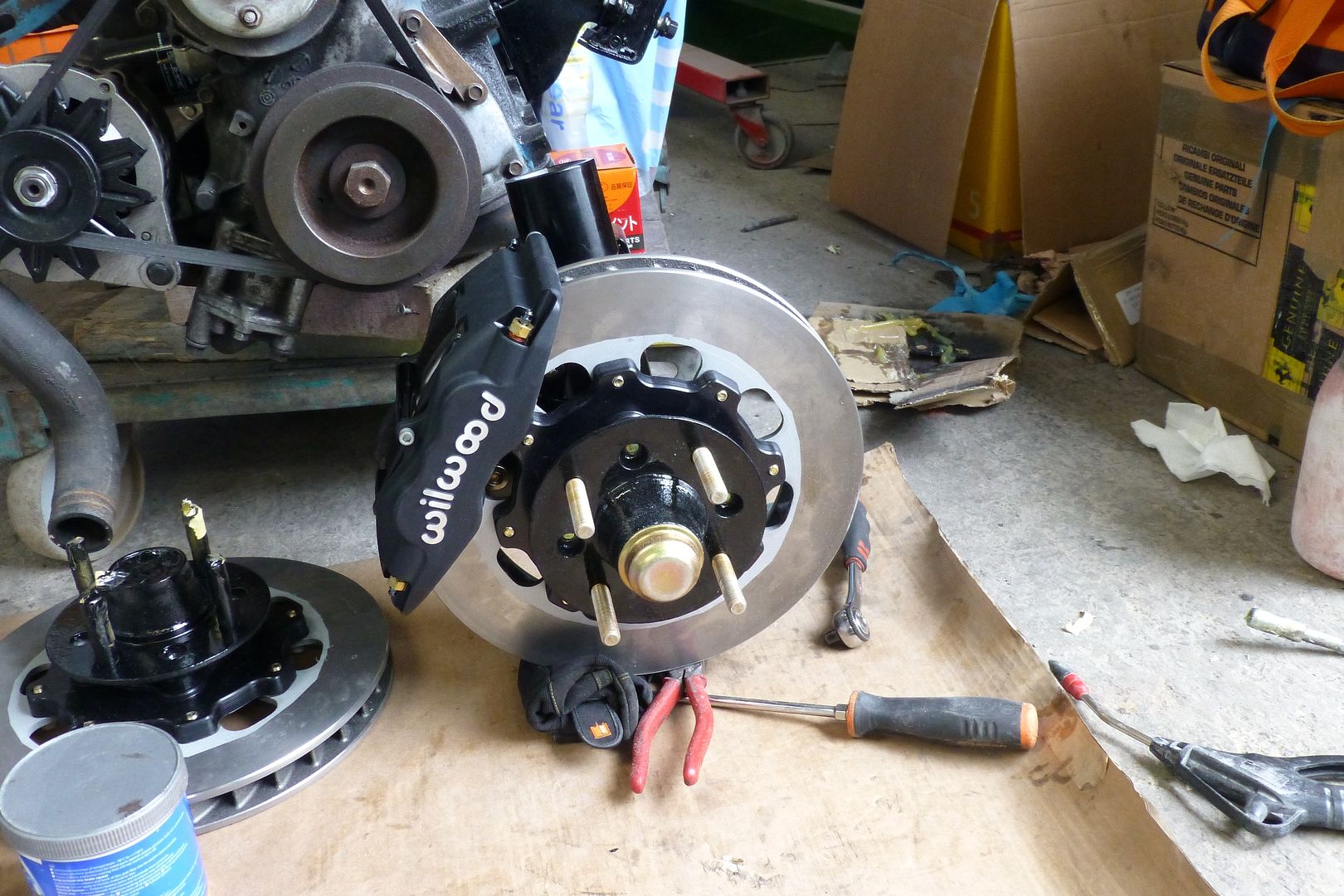

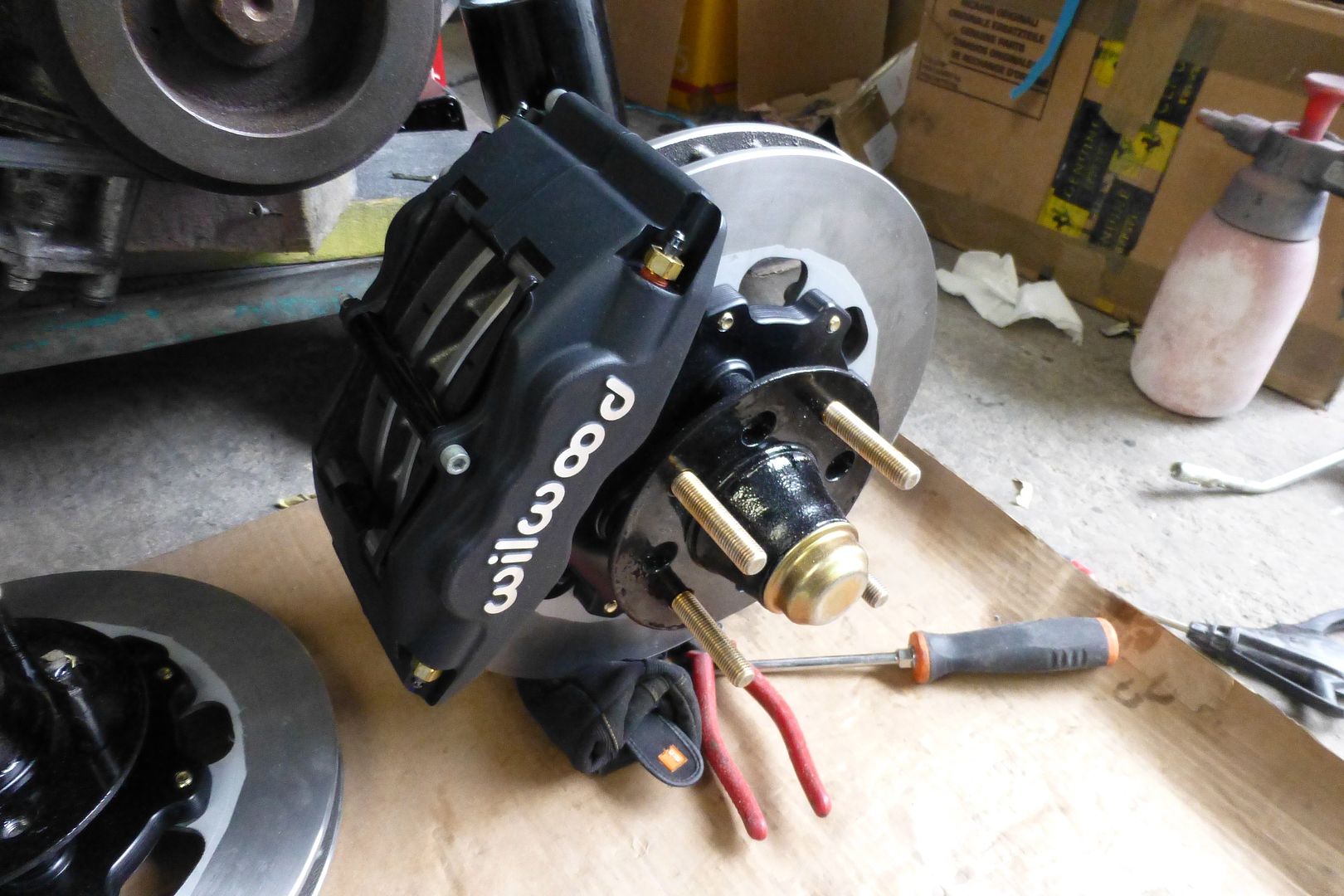

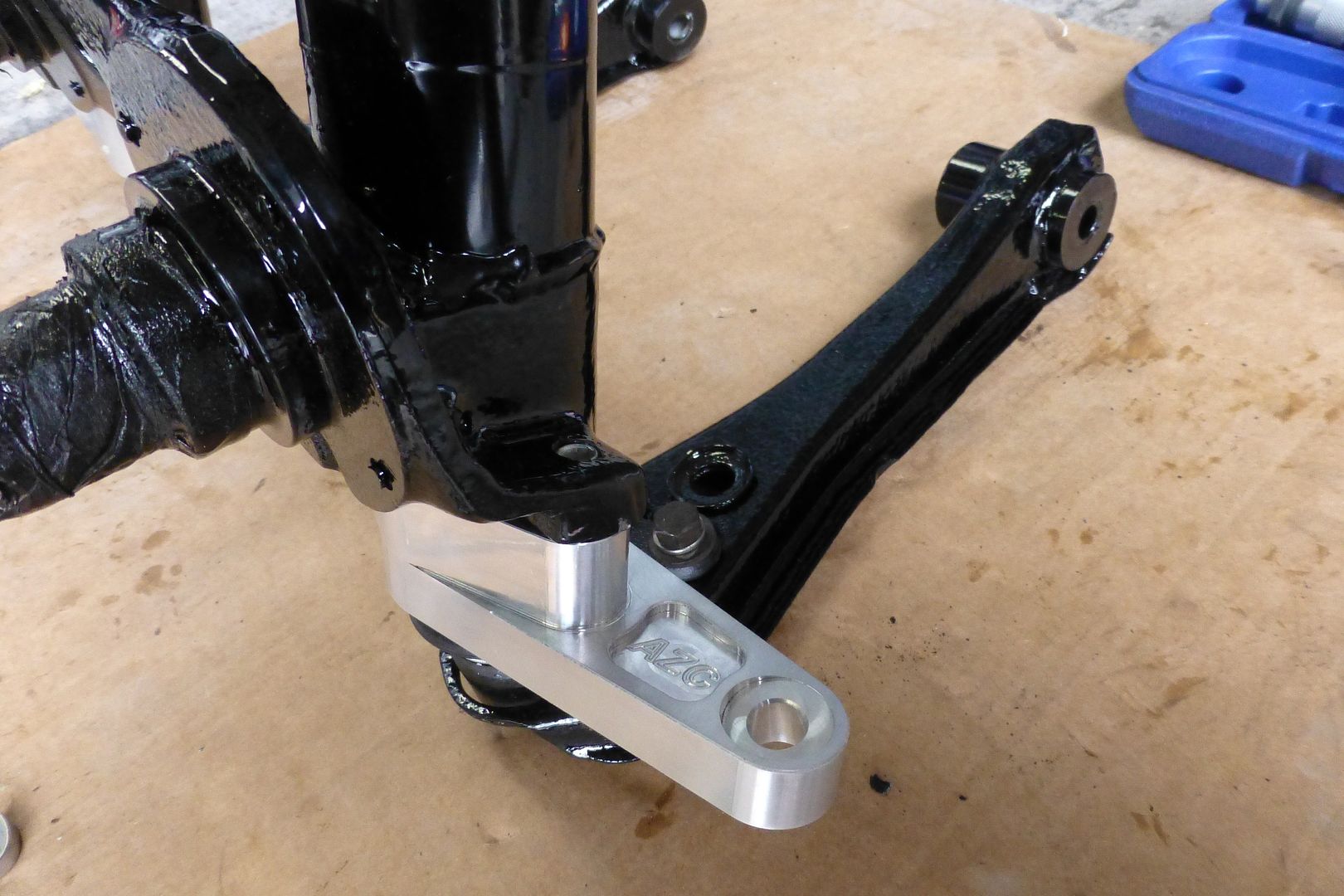

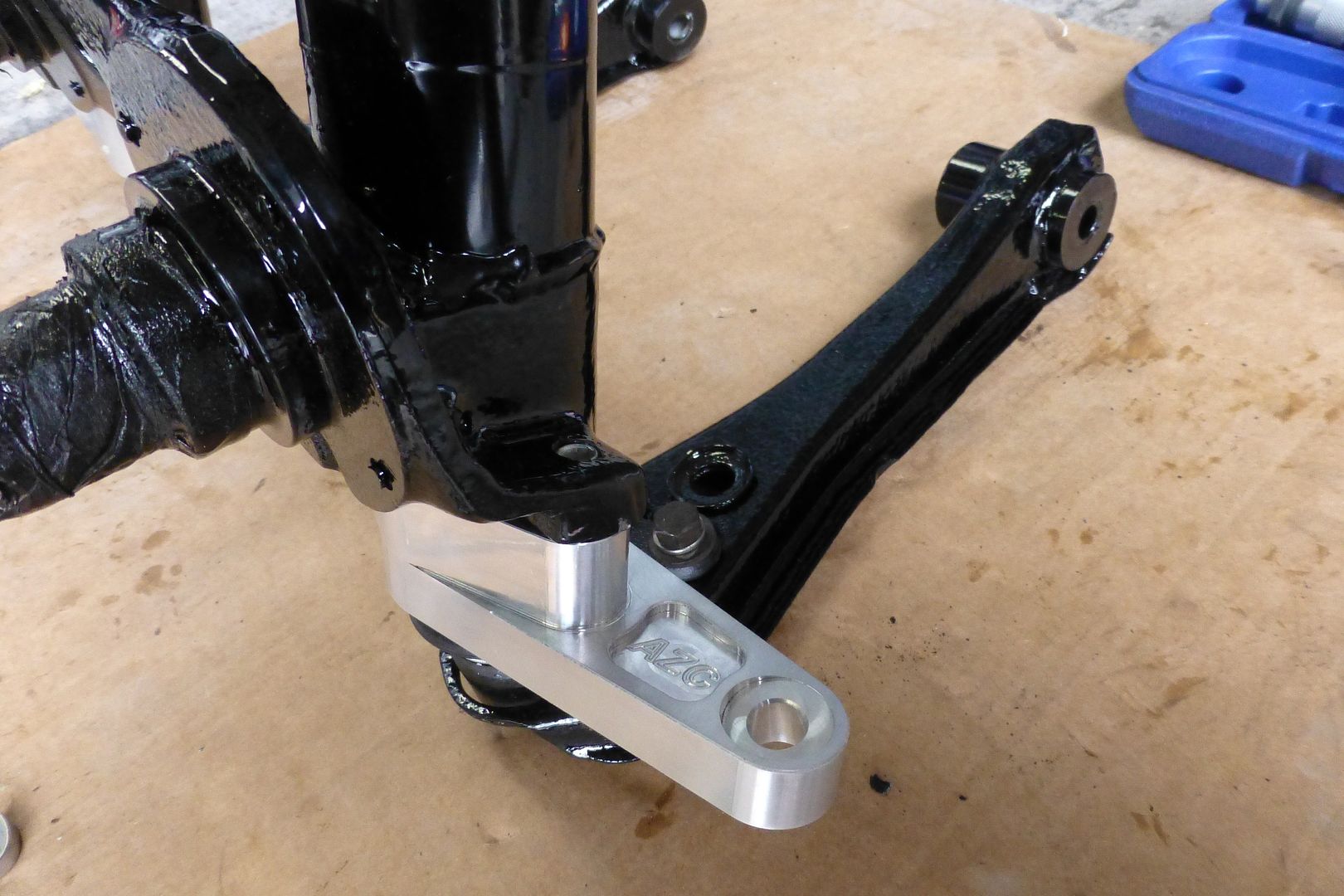

Started rebuilding my hub/suspension/control arm:

Couldn't resist trying a coilover in it:

You can see how badly this has been welded/repaired previously, bad pigeon **** welds not even ground down, random patches of metal rather than a full section cut to shape, theres even a few holes in the lines, this will all be fixed properly and strengthend.

Repainted the new shafts as I wasn't happy with the paint on them, also painted the cv's in a funky blue:

Bought some nice wheel nuts, they have to be open as I've got extended wheel studs all round. I had bought some cheap chrome ones but not all of them threaded on nicely and they galled badly on the wheels. These ones are very light (only 26 grams each) look great and the top of the seats spin freely from the main body so that they don't damage the wheel and allow equal torqueing all round:

New clutch master cylinder as my original one had seen better days, works fine but was quite corroded at the back:

Battery cable cut to the correct lenths, battery mounted power shut off switch, some more random wiring and a steering wheel cover to keep my new wheel clean:

Rebuilt my steering rack today and mounted it on the crossmember:

Got the engine built back up:

Started rebuilding my hub/suspension/control arm:

Couldn't resist trying a coilover in it: