. Please do show these little improvements you're doing in the engine bay - they are the details that go unnoticed and appreciated but some require a fair amount of thought in their innovation and execution.

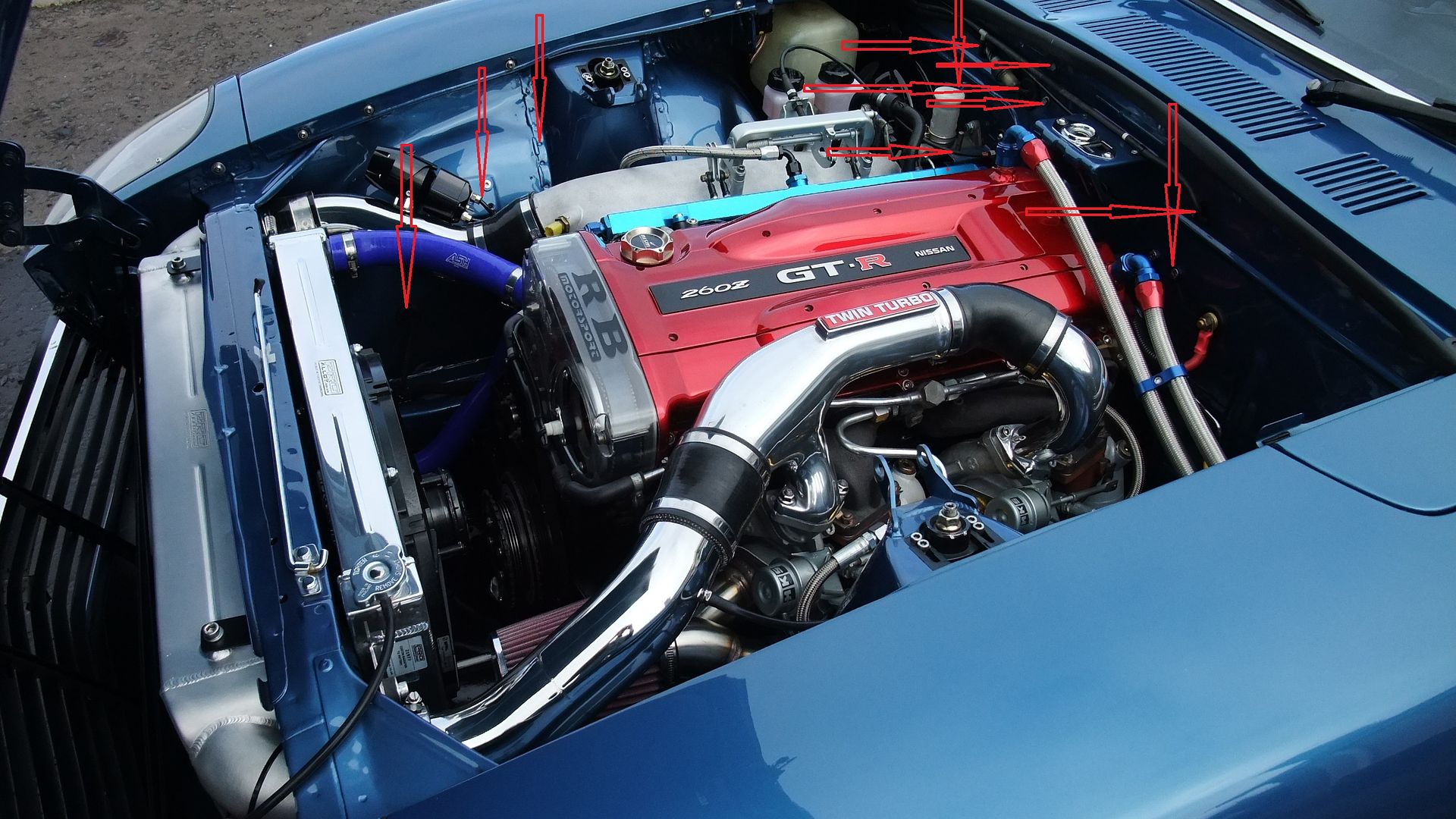

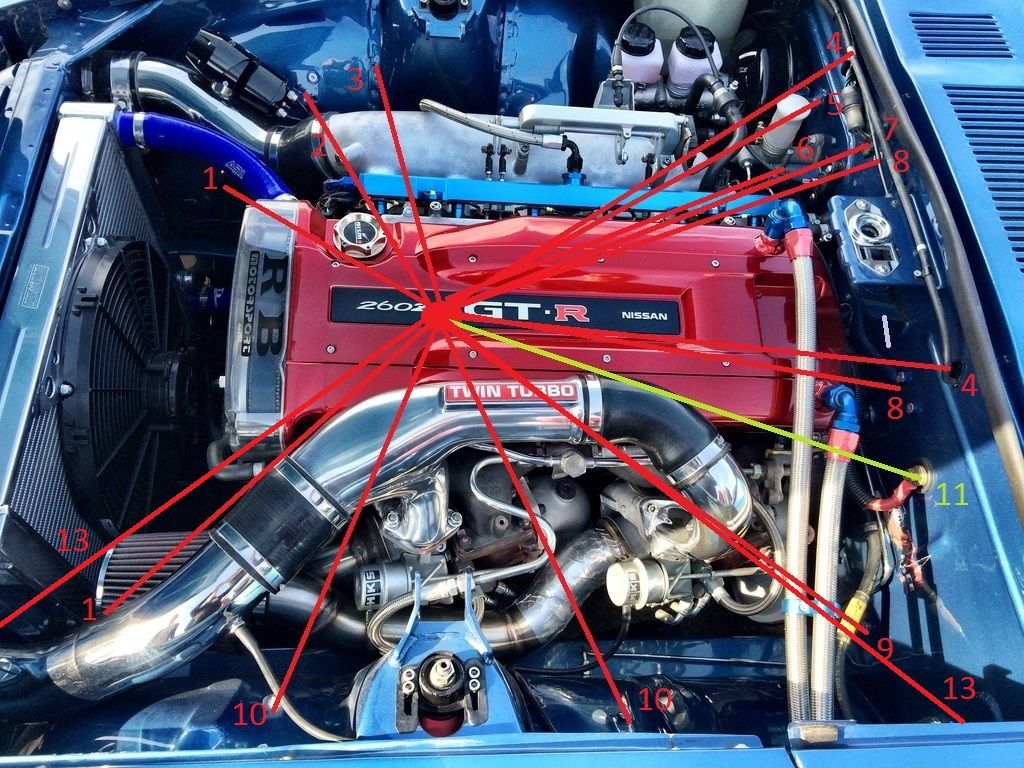

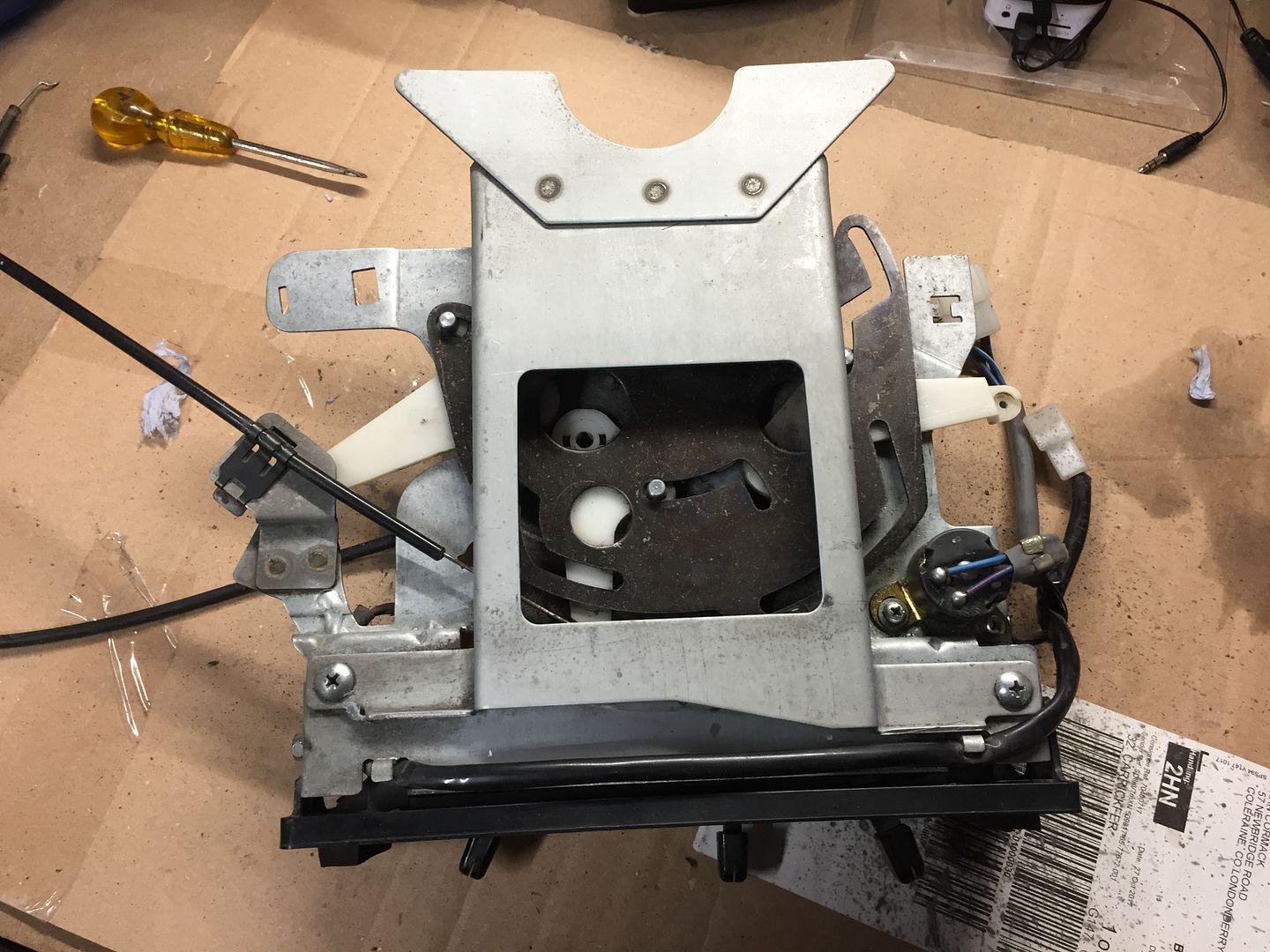

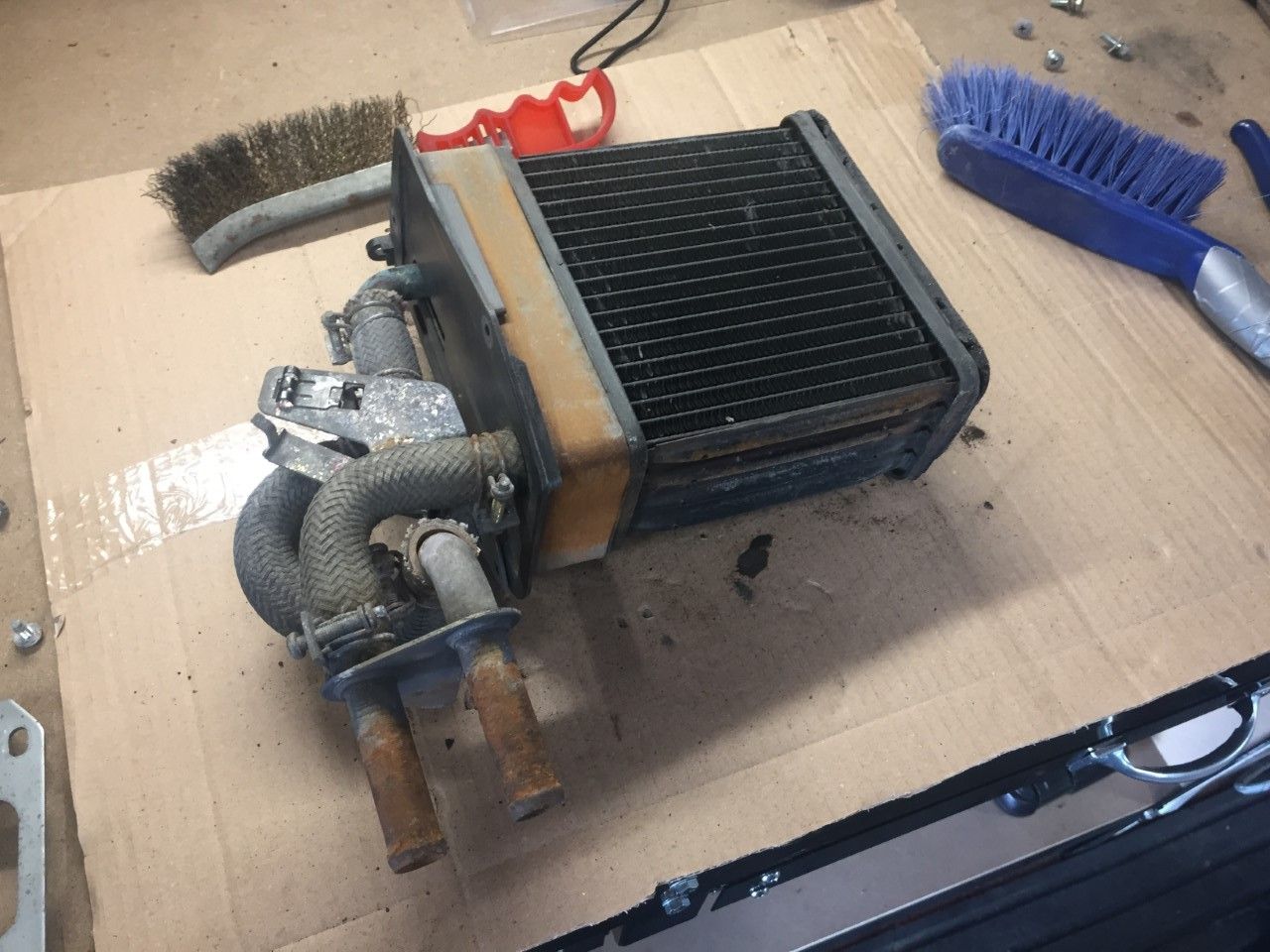

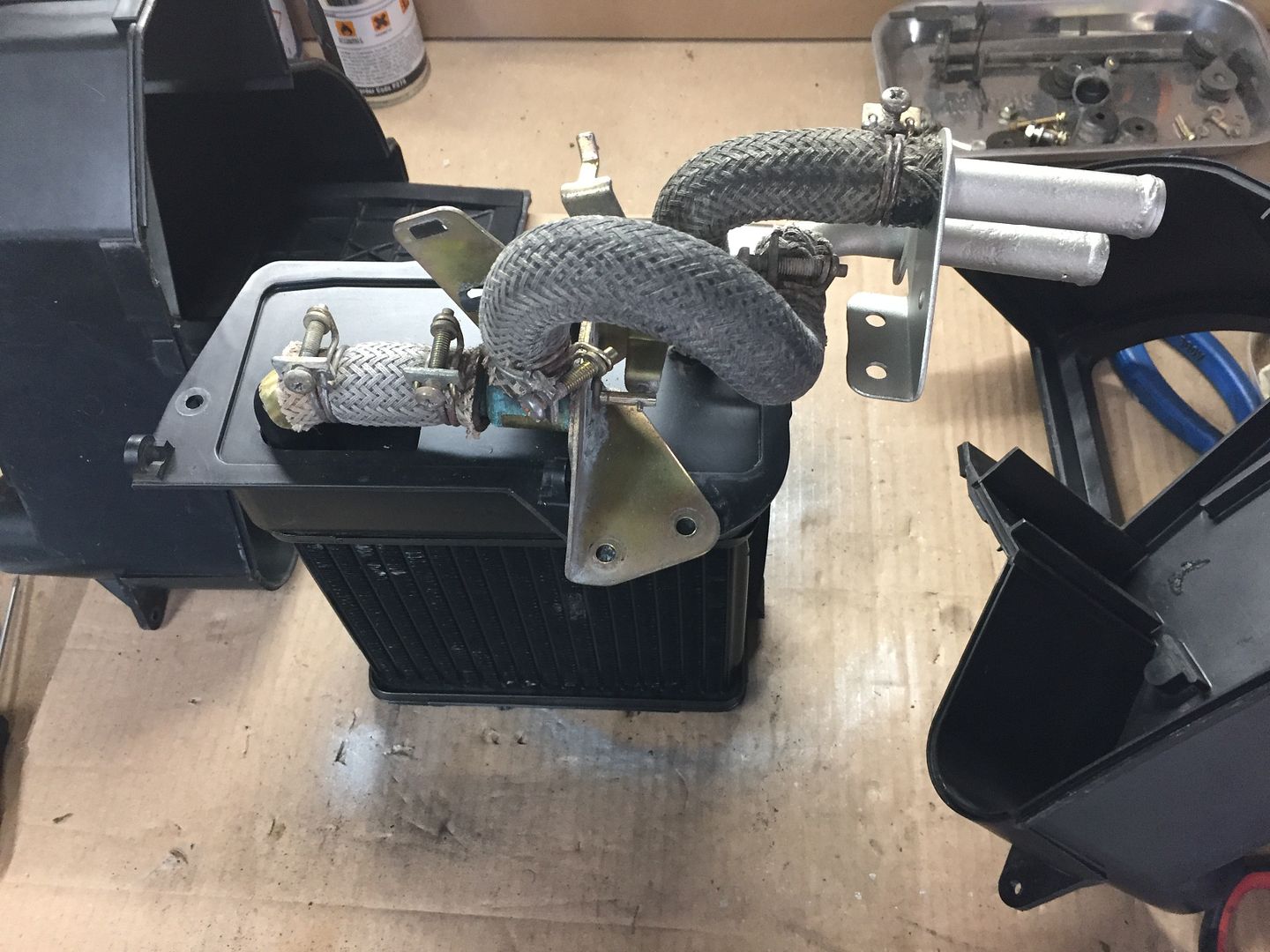

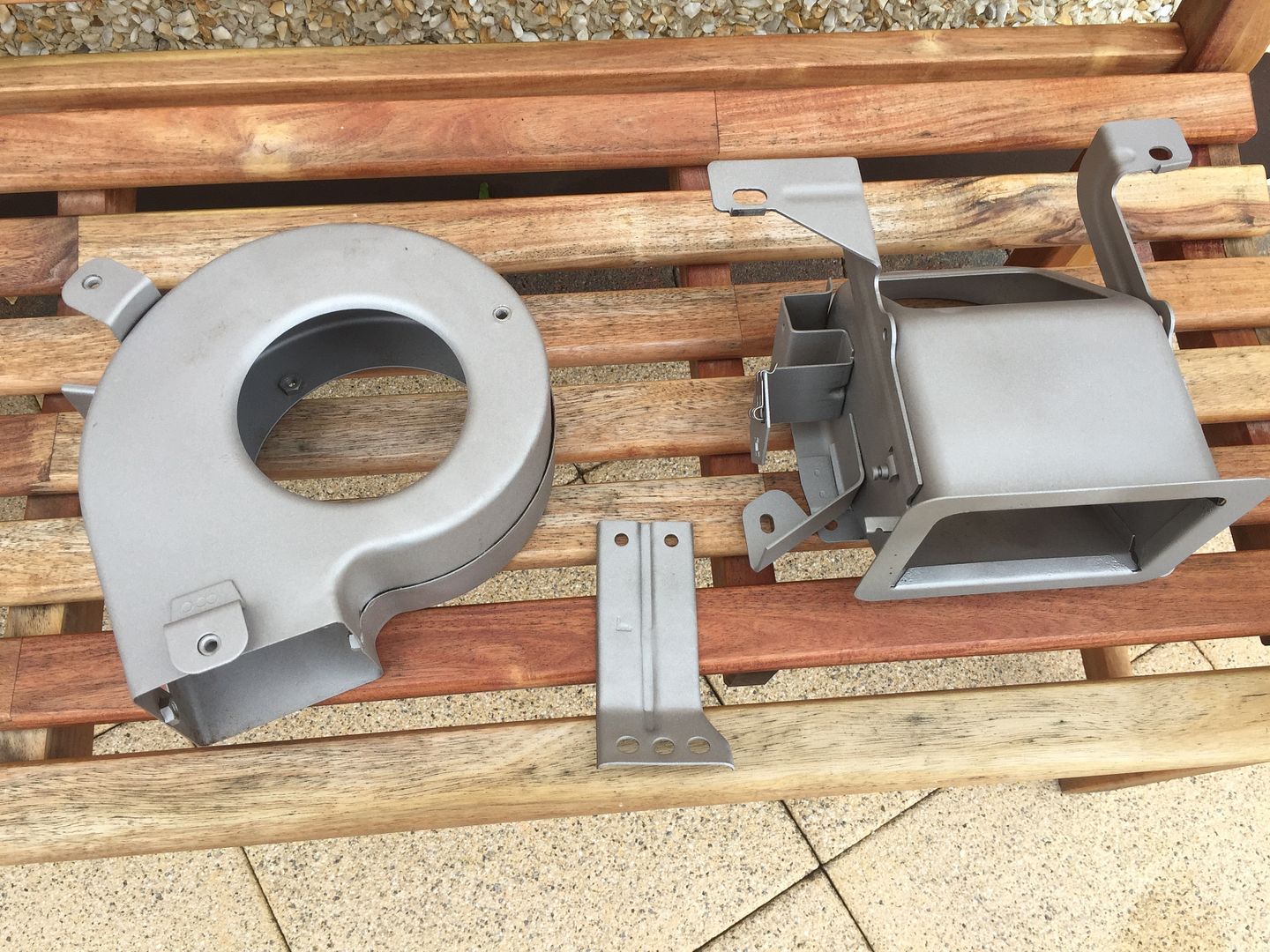

Here are some of the changes/improvements being made in the engine bay:

1: Both holes for headlight wires being removed, they will be tucked to run underneath the front.

2: Bolt holes being removed/smoothed

3: All spot weld dimples being smoothed off

4: Washer fitting being relocated inside scuttle panel for cleaner look thus removing both the fittings and the tube going to them

5 & 6: Unused brackets being removed

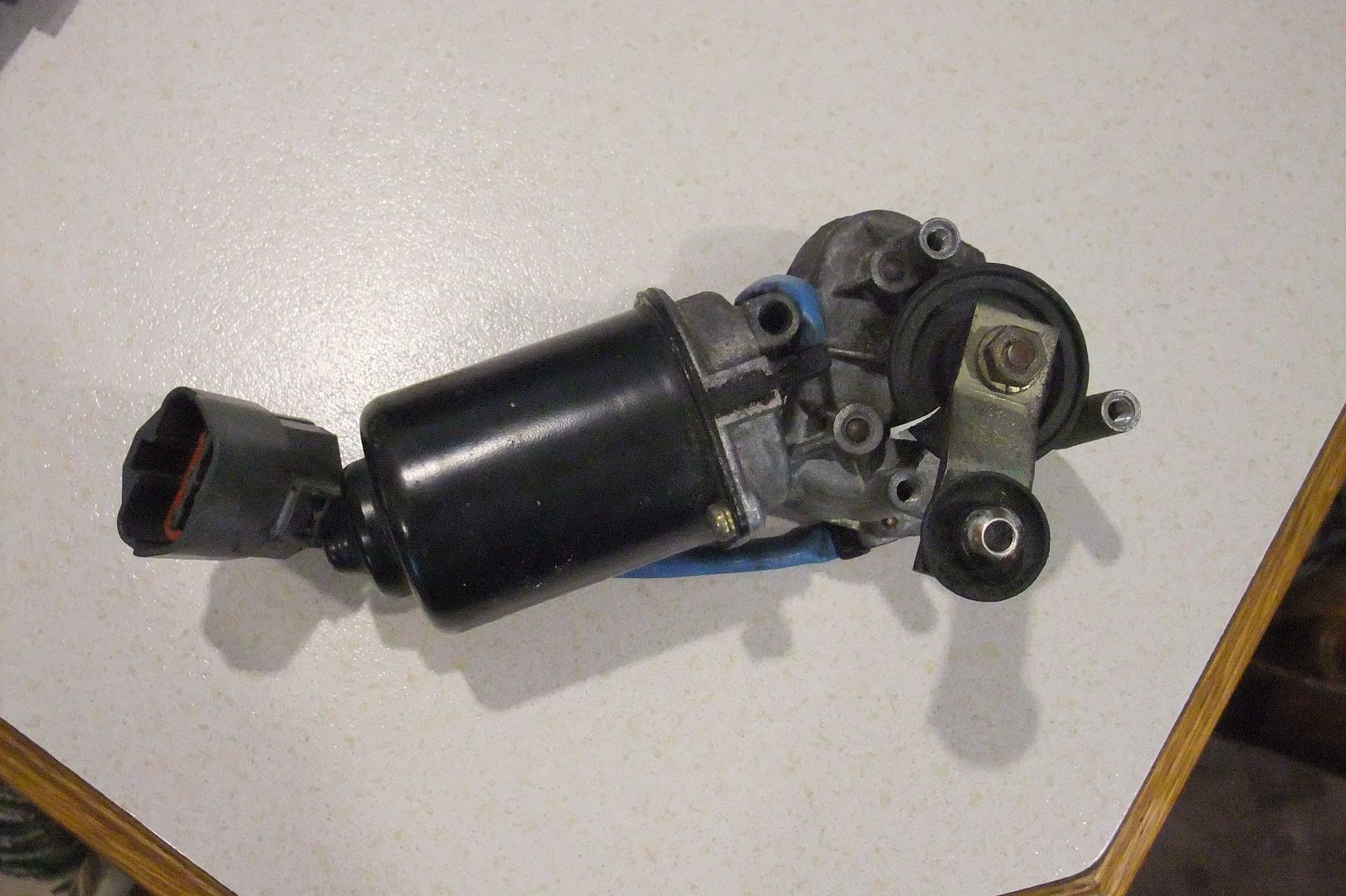

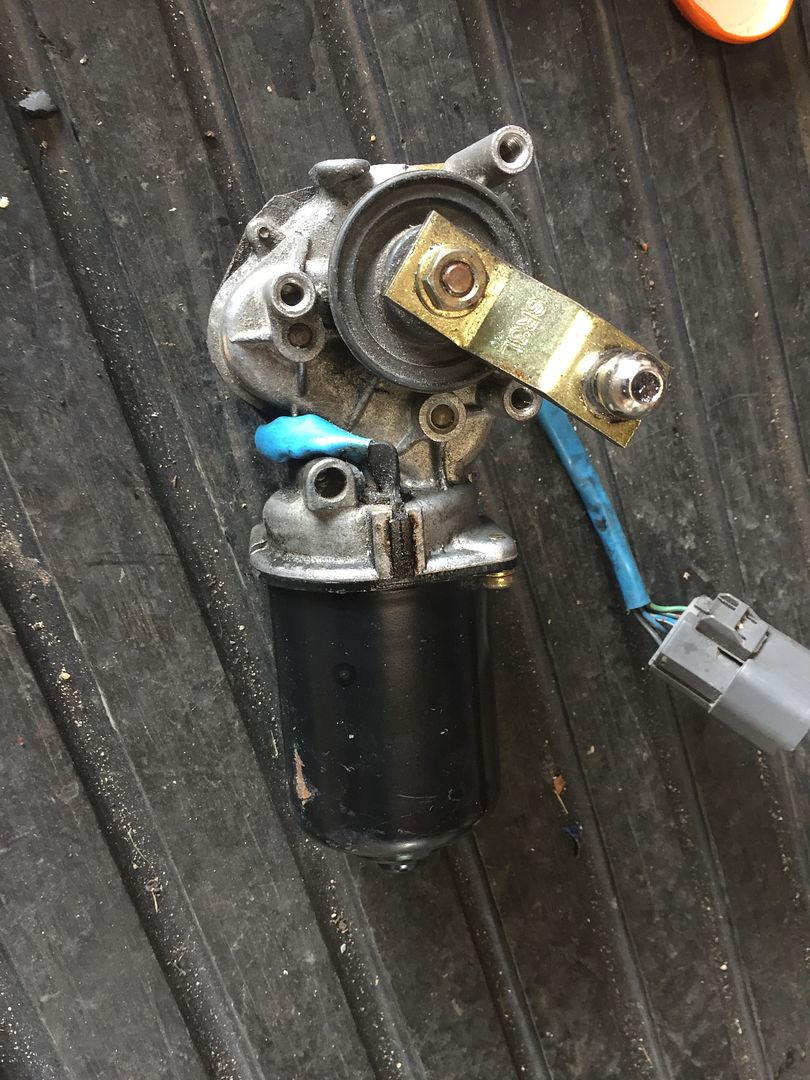

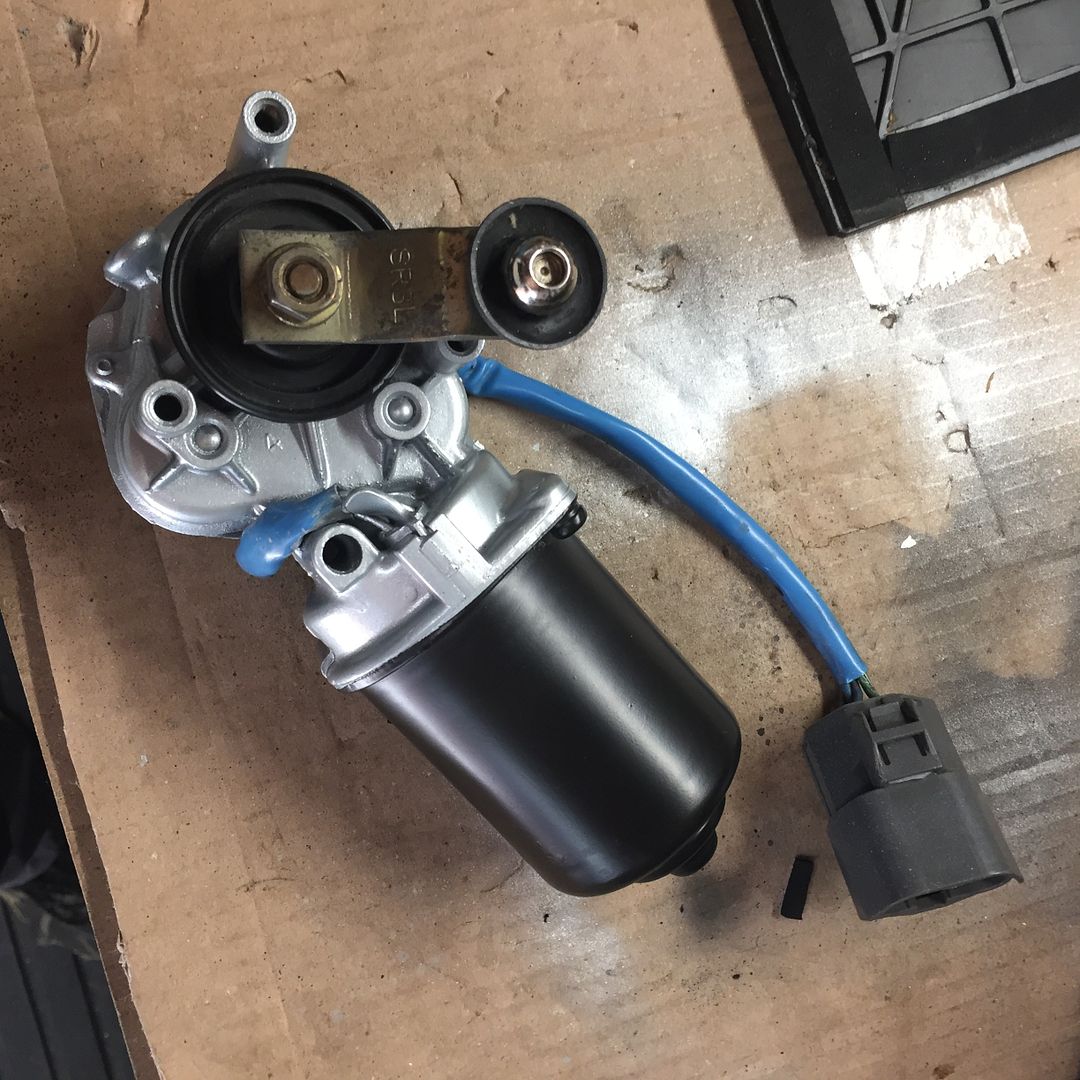

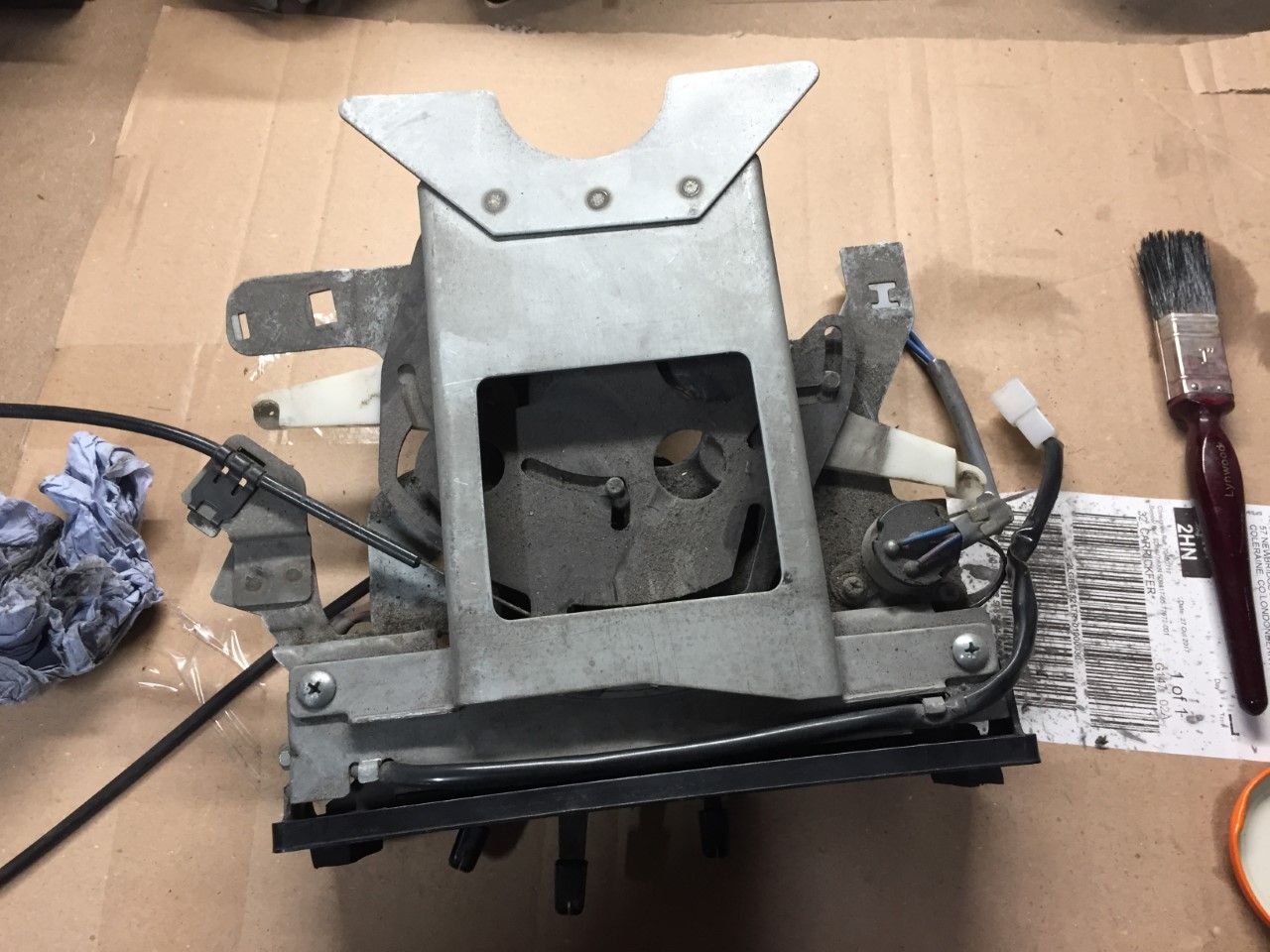

7: Wiper wiring and hole through bulkhead being removed, wiring will be run under scuttle panel from far side of bay

8: Unused bolt holes being removed

9: More unused bolt holes

10: Yet more bolt holes to be removed and smoothed

11: Wanted to relocate this but couldn't find anywhere else suitable

12: The pass side hole for the intercooler piping is being enlarged as its too tight a fit at the moment an I want change this to an HD clamp fitting.

13: There are some more areas not visible in the photos where there are holes, unused brackets and so on that will also see work.

)

)